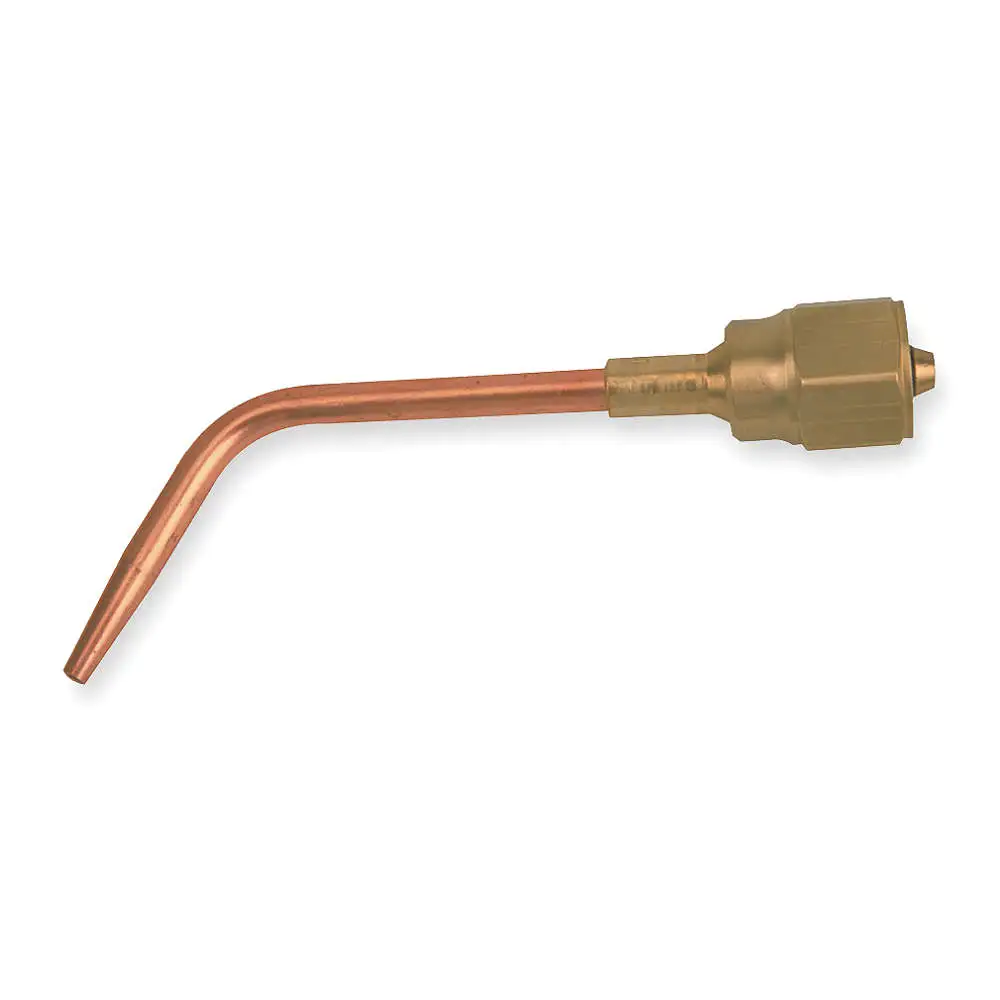

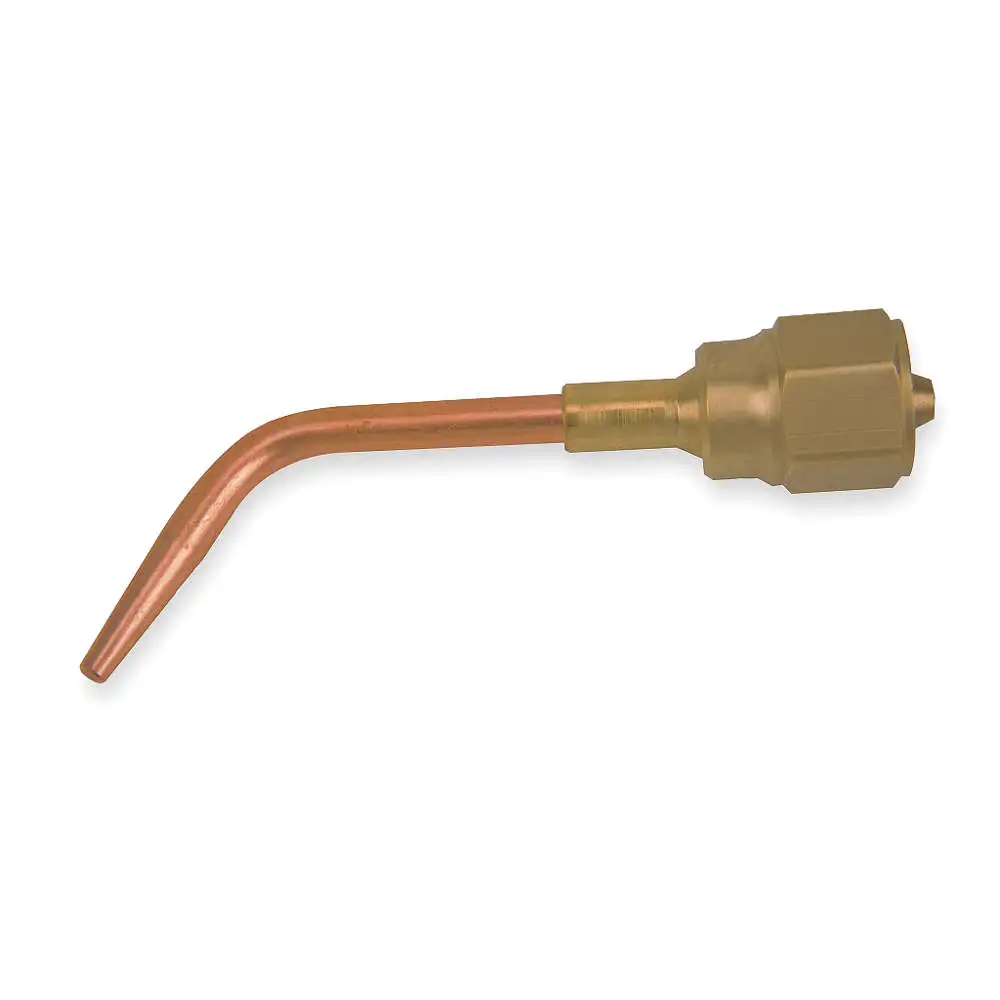

Nozzle Welding

Victor nozzles are designed for directing the welding gas (acetylene / hydrogen) into the weld puddle, protecting the tip against molten metal formed by high-temperature flame. These nozzles are used in conjunction with torch handlesfor purposes like structural steel fabrication, repair and maintenance and light fabrication tasks in various metalworking facilities. Victor welding nozzles have copper construction for withstanding high gas pressure and flame temperature while retaining the tip shape and structure. Victor nozzles have individual spiral mixers that provide clean and well-directed flame for ensuring precise welding throughout the operation. They have built-in snap rings and brass coupling nuts for protecting the cone end against damage & wear. These nozzles can be fixed onto the torch handles without using additional tools, such as a wrench, and feature double O-Rings for providing gas-tight connection when installed. Victor nozzles have a 65-degree tip angle for ensuring easy welding and providing long cone flame output. These welding nozzles are compatible with hydrogen and acetylene welding gases and suitable for preheating applications.

Uses

Victor nozzles are used with torch handles and welding sets for directing the welding gas (acetylene / hydrogen) into the weld puddle to protect the tip against molten metal formed by high-temperature flame. These welding nozzles are suitable for structural steel fabrication, repair and maintenance and light fabrication tasks in various automotive, manufacturing, maintenance & repair and metalworking facilities.

Working Mechanism

Victor nozzles are attached to the torch handle (through a brass coupling nut) that is further connected to the welding set and gas cylinders. The torch handle supplies and control the flow of gas to the welding nozzle. These welding nozzles have spiral mixer design and deliver clean & well-directed flame. Victor nozzles provide a lone cone type flame for welding the workpiece.

Frequently Asked Questions

What are Victor welding nozzles made of?

Victor nozzles are constructed from copper alloy and are used in conjunction with acetylene gas. These welding nozzles are machined with either 6 or 4 preheated holes. These welding nozzles can handle light, medium and heavy preheats with ease.

Why is there a difference in torch tip sizes?

Cutting tips / nozzles vary based on application and fuel gas type. A one-piece tip is ideally used for the oxygen-acetylene application, while a two-piece tip / nozzle is used for oxygen alternate gas (propylene, natural gas, propane etc.).

What are heating nozzles?

Heating / preheating nozzles like Victor nozzles provide large volumes of heat for various operations, such as bending, brazing, forming, shrinking, straightening, preheating and more. Preheating and heating nozzles deliver quick and concentrated heat for maximum efficiency.

What is the difference between a gas welding nozzle and a gas cutting nozzle?

Gas welding nozzles have a single hole in the tip in which oxy-acetylene mixture burns & exits the nozzle. Cutting torches have the same single hole in the tip. However, they also have a ring of small holes around the nozzle. These surrounding holes on the nozzle are to feed additional oxygen to the flame when the oxygen lever is pushed on the cutting handle.

How to replace a welding tip?

Welding tips, when worn out, can be easily replaced. These welding nozzles have brass connectors that can be easily screwed out to remove the welding nozzle from the cutting torch. Once removed, the welding nozzle can be replaced without using any additional tools like a wrench.

Does the brand offer additional products?

Yes, Victor also offers various cutting torches, welding kits, individual connectors, cutting nozzles and gas gauges.

Change Country

Change Country