Destaco offers a wide range of products like manual clamps, pneumatic clamps, clamp accessories and many more. The brand's straight line action clamps are designed to hold a workpiece by pushing it towards a surface. Destaco 603 Series straight line action clamps are ideal for use as both push & pull clamps as they can be locked in both extended and retracted positions. Destaco 604 Series straight line action clamps on the other hand, feature adaptable and compact design due to their threaded body that provide a through hole mounting.

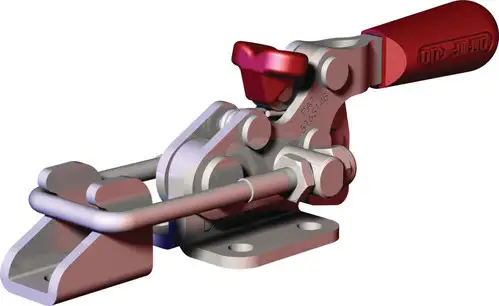

The brand also manufactures pull action latch clamps featuring handles to place a clamping pull bar or hook around an opposing workpiece latch that is horizontally or vertically oriented to the clamp base. These clamps provide a powerful closing force and a thumb control lever for positive holding and convenient single handed operation. They are generally offered in fixed latch, U hook (horizontal and vertical) and J hook type designs. Destaco 323 Series pull action latch clamps are equipped with a horizontal U hook for pulling workpieces that are parallel to the clamp base.

Choose from a wide range of these high-quality clamping products, available in a variety of bar sizes, styles, clamping base, dimensions, materials and load holding capacities on Raptor Supplies.

Raptor Supplies is not sponsored, endorsed or licensed by, or in any way affiliated with, Destaco.

See More

Change Country

Change Country