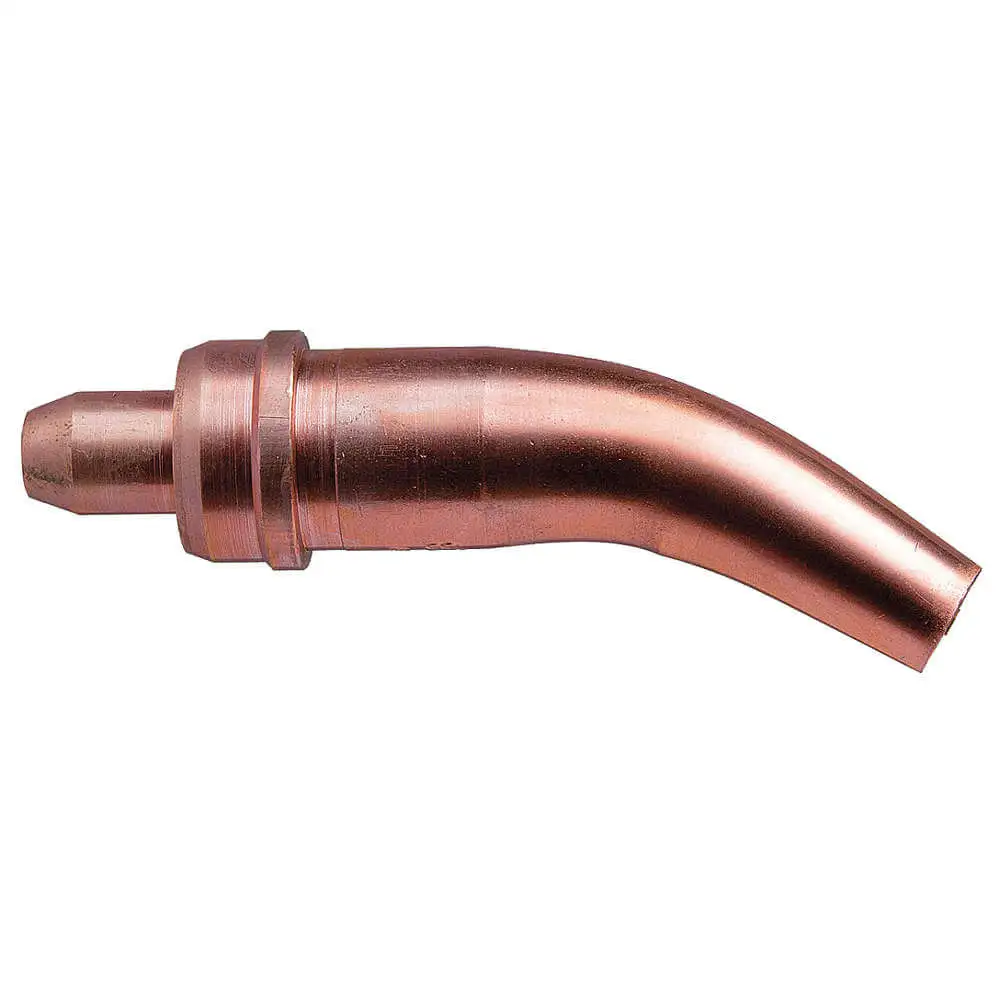

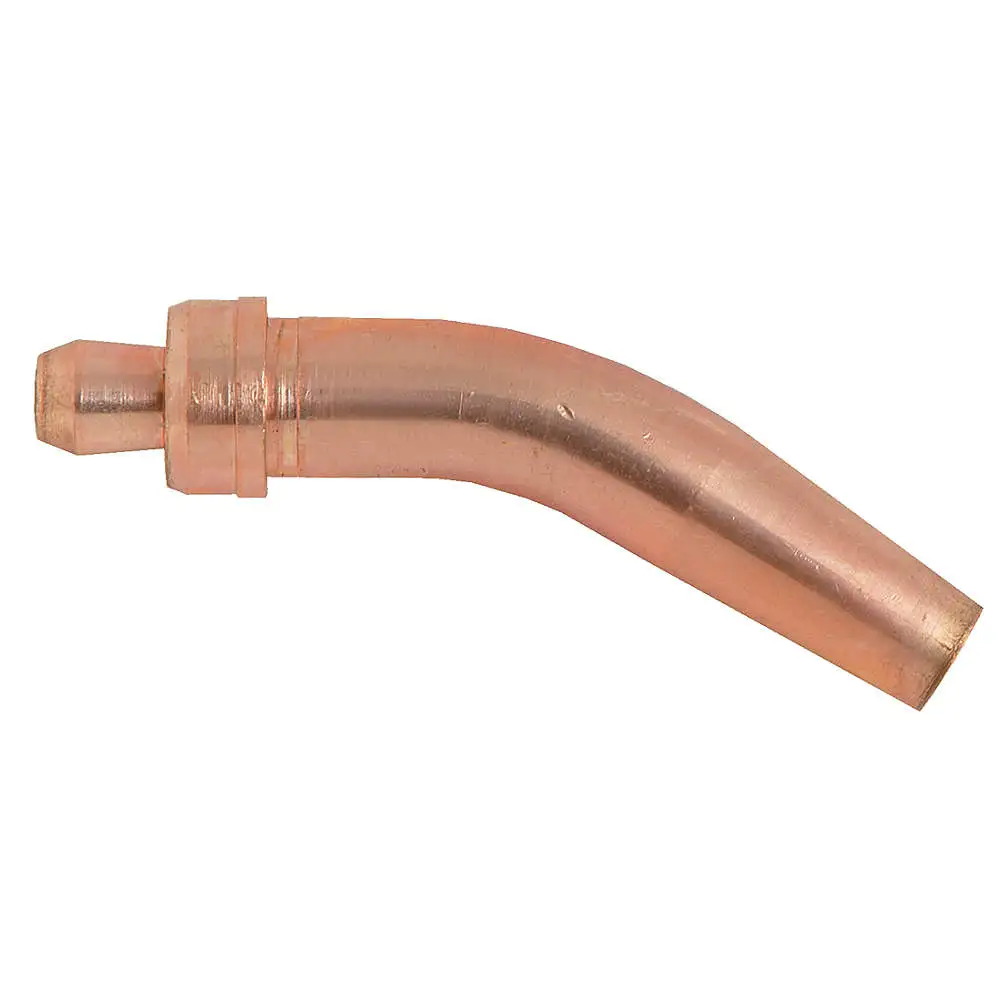

Cutting Tips

Gas welding equipment, such as gas welding torches or gas cutting torches, use oxygen and fuel gases like propane, propylene, acetylene & natural gas for welding, heating & cutting metallic workpieces. These welding equipment are available in variants having cutting, brazing, soldering & heat shrink attachments for performing numerous operations.

Victor Thermal Dynamics, an ESAB brand manufactures cutting, gas control and speciality welding tools for diverse applications in automotive, manufacturing, oil & gas and fabrication industries.

Victor Thermal Dynamics gas welding & cutting tipsare attached to welding, heating or cutting torches that are powered using gas welding equipment.

Victor cutting tips are used to generate highly focused neutral flame for cutting or gouging metal workpieces precisely. They have a smooth tip surface for optimum heat transfer and reduced spattering. These Victor cutting tip outlets generally feature orifice-like design having separate outer & inner gas outlets. These Victor cutting tips have straight / angled heads and short / long tips for cutting workpieces at diverse angles and distances. Selected models of these Victor cutting tips have specialised orifice design variants for heavy-duty preheating, removing welds and other applications. These Victor cutting tips are available in variants compatible with acetylene, propylene and propane / natural gas.

Uses

Victor cutting tips are ideal for cutting metal & metal alloy workpieces when attached to gas cutting torches or gas cutting outfits. These Victor cutting tips are used for fabrication, construction and repair & maintenance applications in railroads, shipyards, farms and automobile shops.

Frequently Asked Questions

What is the main difference between a cutting torch and a welding torch?

The basic difference between a cutting torch and a welding torch is that the former is used to cut metals into smaller pieces, while the latter is ideal for joining different metal pieces together. Cutting torches generally use differently sized cutting tips & an additional cutting oxygen lever for cutting, whereas welding torches require welding nozzles and optional filler material for combining two metal pieces. These torches are application-specific and can not be used interchangeably.

What are some troubleshooting techniques for this Victor Thermal Dynamics cutting torches & outfits?

- Check torch handle, cutting attachment, Victor cutting tips and other parts for clogged debris or metal particles.

- Check for any cracks or breaks for preventing acetylene or oxygen leaks.

- Check that the valves, hoses & pressure gauges are delivering correct pressure from tanks into the torch lines.

- Make sure that cutting attachment & Victor cutting tips are tightly secured on the torch handle.

What are some key points users should keep in mind while selecting a Victor cutting tip?

- Metal Thickness: Victor cutting tips deliver different amounts of oxygen & fuel gas at different pressures & flow rates from their orifice (both centre & pre-heat orifice) for cutting specific metal thicknesses. So users need to select the right Victor cutting tip according to the thickness of the metal to be cut.

- Application: Victor cutting tips are available in diverse designs with a wide range of head angles, length and orifice size & shapes for performing specific applications. Different Victor cutting tips are used to cut, gouge and heat metal workpieces. Users should refer to their manual for checking that the chosen Victor cutting tip is compatible with their cutting torch or attachment.

- Fuel Gas: Oxy-fuel cutting involves the use of various types of gases. Users should check the compatibility of the selected Victor cutting tip before using it. By optimising the way oxygen and fuel gas are delivered, cutting tips are designed differently for each fuel gas.

How hot is the flame generated by Victor cutting tips?

The temperature at the tip of flame in front of Victor cutting tips may reach up to 6000 degrees F, depending on the ratio of oxygen to fuel gas used.

€ EURChange Country

€ EURChange Country