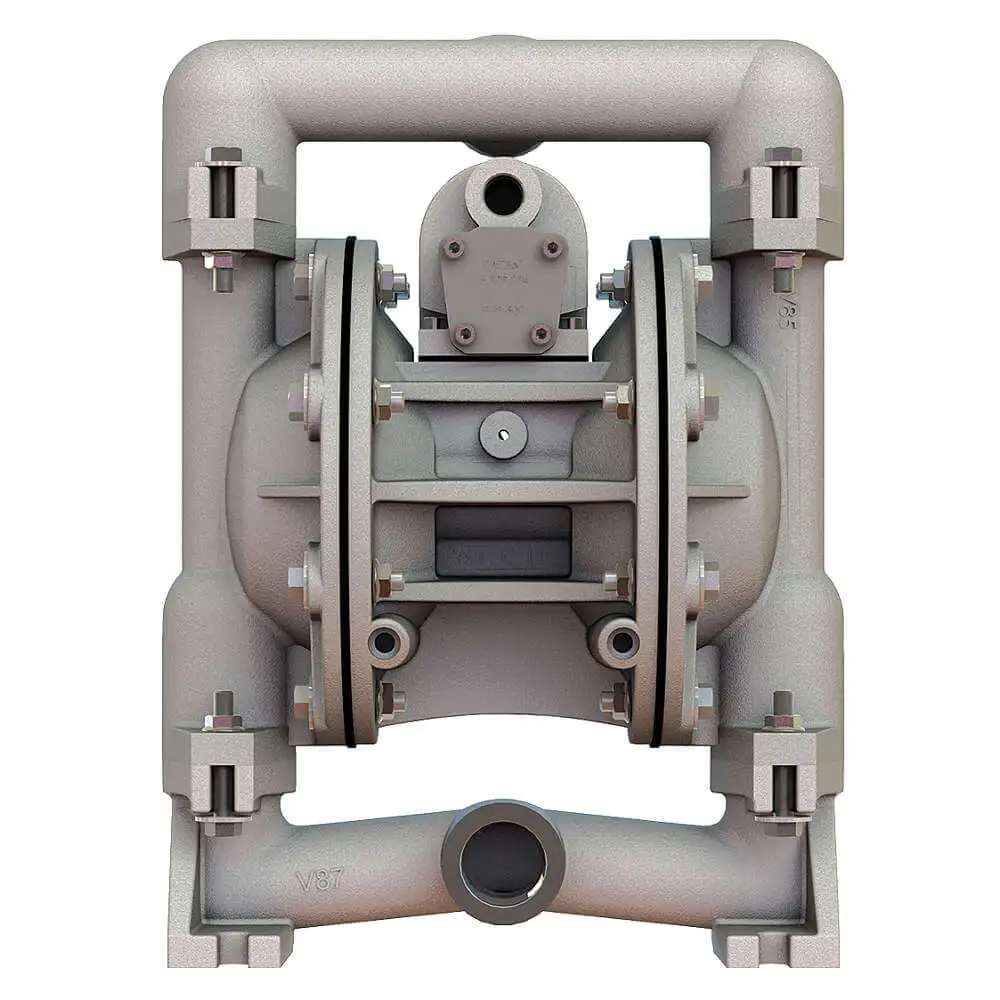

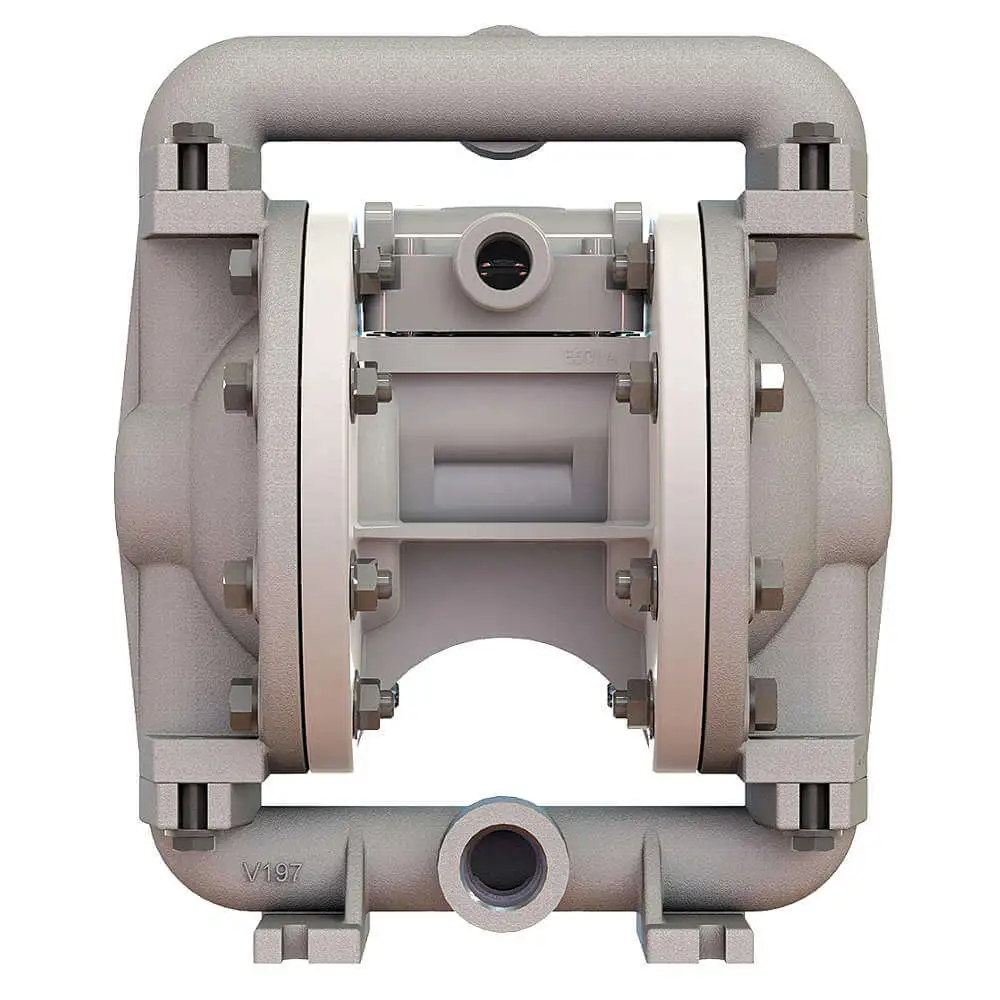

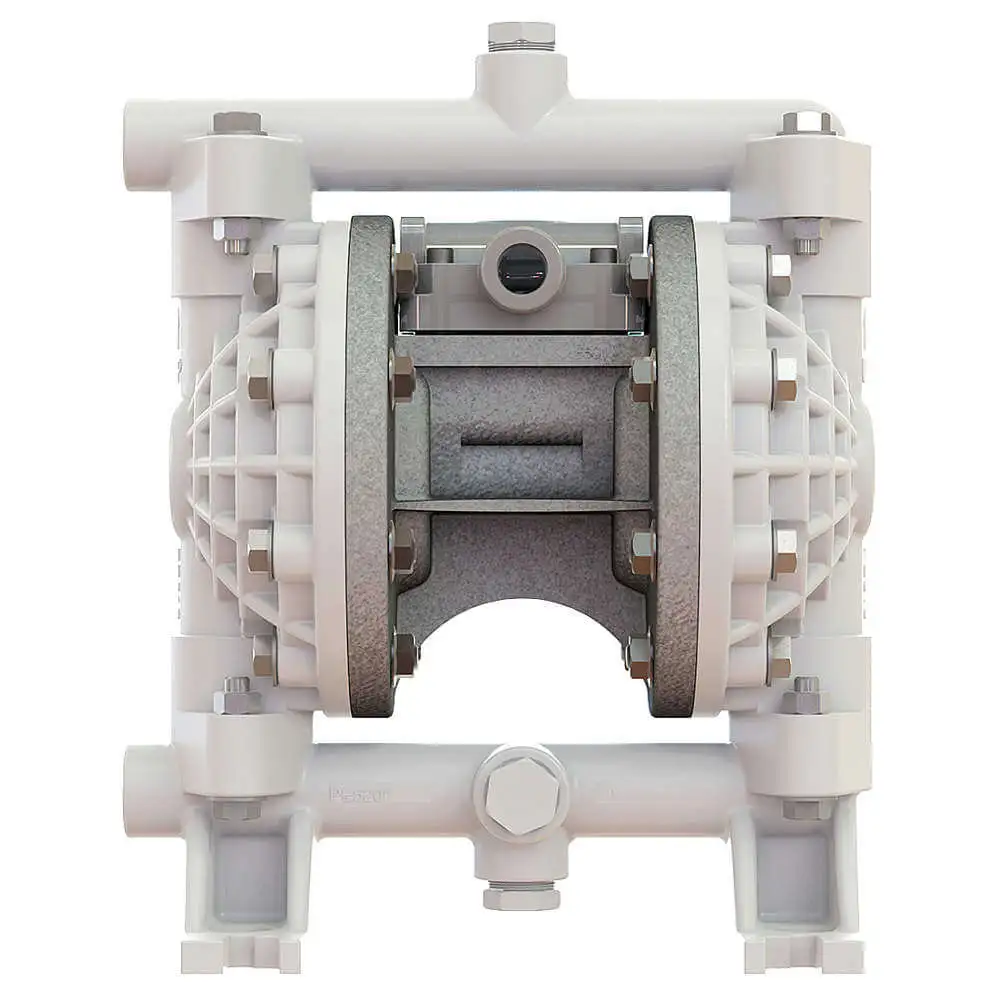

Versa-Matic E1SA5T559C-ATEX diaphragm pump is suitable for transferring liquids, such as chemicals, oils and solvents. Its design, featuring diaphragms that move back and forth, enables efficient pumping without exposing the fluid to mechanical parts. This makes it suitable for applications where contamination must be minimised, such as in chemical processing plants, oil refineries and hazardous environments.

Features:

- It has 316 stainless steel housing material, ensuring long-lasting performance in various environments.

- This double diaphragm pump has a self-priming feature, simplifying the setup process and ensuring efficient operation.

- It includes a reliable ball valve type, providing smooth fluid control with minimal maintenance requirements.

- This double diaphragm pump further features multiple flow rate options, ranging from 26.5 to 48.2 gpm, catering to different application needs with precision.

- This double diaphragm pump features a pump assembly type of bolt, ensuring secure and stable construction for reliable performance in demanding applications.

- It has a diaphragm and valve material of PTFE, ensuring excellent chemical resistance and reliable performance in handling a wide range of fluids and chemicals.

Frequently Asked Questions:

Q. What power source does this diaphragm pump require?

A. This pump can be powered by compressed air, with an air consumption rate of 50 standard cubic feet per minute (SCFM) and a rated air pressure of 125 PSI.

Q. What type of connections does this pump feature for fluid intake and discharge?

A. This pump is equipped with 1-inch NPT connections for both fluid intake and discharge, providing standard connections for easy integration into existing systems.

Q. What safety precautions should I take when using this diaphragm pump?

A.

- Read the manual thoroughly before operating the pump to understand safety guidelines.

- Install the pump correctly according to manufacturer's recommendations to prevent accidents.

- Ensure all fluid connections are tightly secured to prevent leaks during operation.

- Wear appropriate PPE, such as safety glasses and gloves to protect against chemical exposure.

- Operate the pump in a well-ventilated area to avoid accumulation of hazardous fumes.

- Ensure proper grounding of the pump and associated equipment to minimise static electricity buildup.

- Monitor discharge pressure regularly to prevent equipment damage due to overpressurisation.

- Know emergency shutdown procedures and locate emergency stop buttons or valves.

- Provide adequate training to operators for safe pump operation and maintenance.

Change Country

Change Country