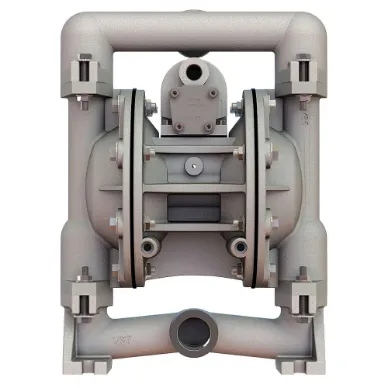

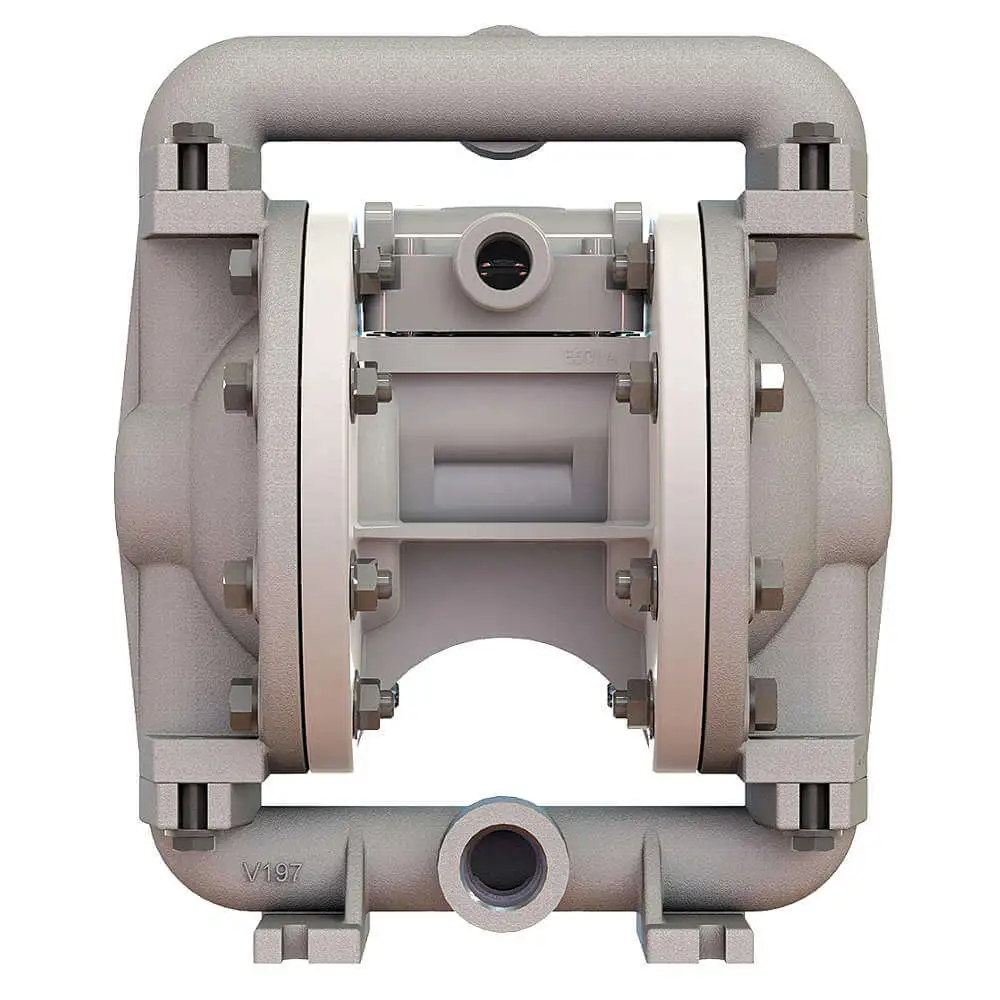

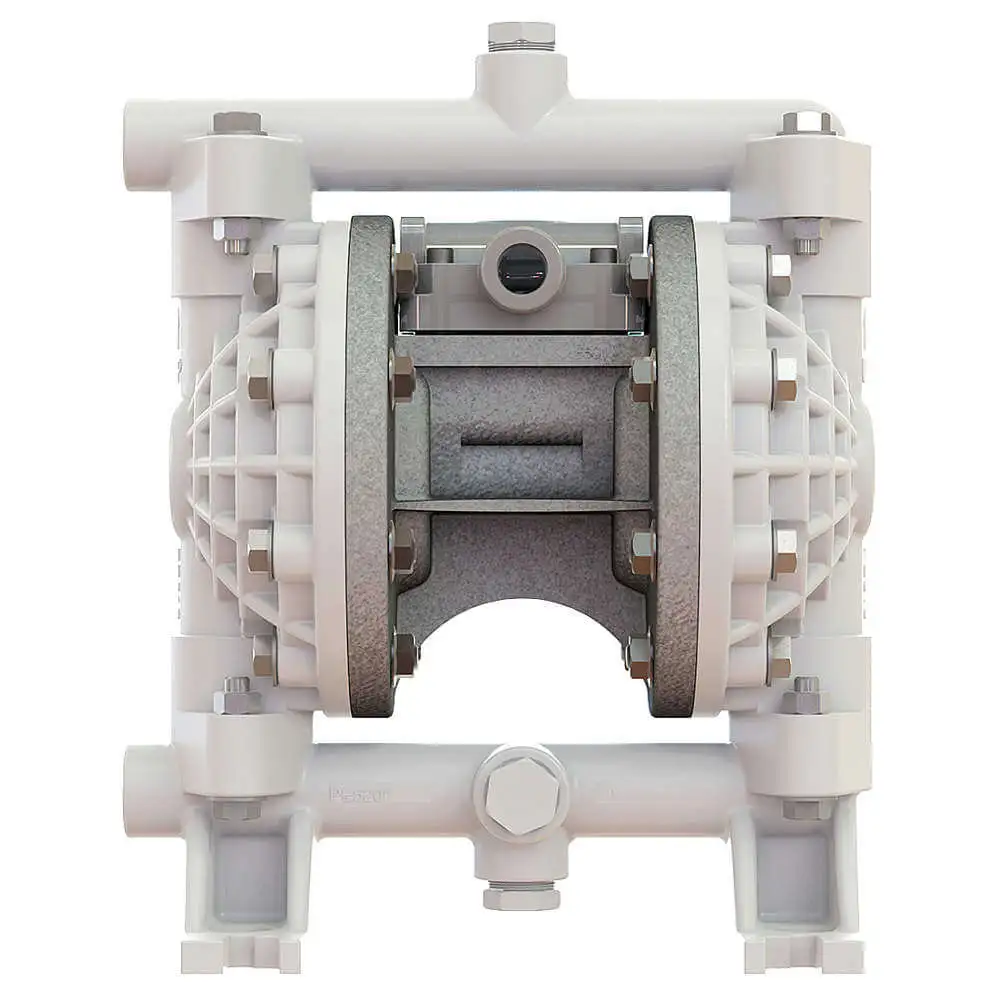

Versa-Matic E1AA5T559C-ATEX diaphragm pump is ideal for transferring chemicals, oils and solvents. Its innovative design, characterised by reciprocating diaphragms, facilitates effective pumping while preventing direct contact between the fluid and mechanical components. This feature ensures minimal contamination, making it well-suited for environments where cleanliness is crucial, such as chemical processing plants, oil refineries and hazardous locations.

Features:

- This double diaphragm pump has self-priming features for simplifying the setup process and ensuring efficient operation.

- It comes with a ball valve to provide smooth fluid control with minimal maintenance requirements.

- This diaphragm pump features multiple flow rate options, ranging from 26.5 to 48.2 gpm, catering to different application needs with precision.

- It further features aluminium housing material, offering durability and lightweight construction for ease of handling and transport.

- This double diaphragm pump offers a bolt pump assembly, ensuring secure and stable construction.

- It has a diaphragm and valve made of PTFE, ensuring excellent chemical resistance and reliable performance in handling a wide range of fluids and chemicals.

- This Versa-Matic E1AA5T559C-ATEX pump has a continuous duty cycle to ensure uninterrupted operation.

Frequently Asked Questions:

Q. How do I determine the correct size of a double diaphragm pump for my application?

A. Major factors include the flow rate required, the viscosity of the fluid, the pressure needed and the temperature conditions.

Q. What is the difference between air-operated and electrically operated double diaphragm pumps?

A. The main difference between air-operated and electrically operated double-diaphragm pumps lies in their driving mechanisms. Air-operated double diaphragm pumps (AODDPs) utilise compressed air to move the diaphragms. On the other hand, electrically operated double-diaphragm pumps (EODDPs) are driven by an electric motor. If you are operating in a remote area or do not have a constant source of electricity but need a pump with the same design, consider Dayton 6PY44 double diaphragm pump.

Q. What safety precautions should I take when using this double diaphragm pump?

A.

- Wear appropriate personal protective equipment (PPE), including goggles, gloves and respirators, to protect against chemical exposure.

- Ensure proper installation and grounding of the pump to prevent the buildup of static electricity.

- Familiarise yourself with the pump's operating manual and follow recommended procedures for startup, shutdown and maintenance.

- Regularly inspect the pump, hoses, fittings and seals for leaks, corrosion or damage.

- Use only fluids and chemicals compatible with the pump's materials of construction to prevent damage or chemical reactions.

- Monitor pressure and temperature gauges during operation to maintain safe operating conditions.

€ EURChange Country

€ EURChange Country