Starrett S154LZ adjustable parallel set is used to level workpieces in layout, gauging & inspection applications during machine tool setup. Its adjustable two-piece construction allows adjustment to exact micrometre sizes, allowing its use as a gauge for checking the size of slots & openings. It can be secured in machine vises for levelling operations during milling, machining, drilling and grinding applications.

Features:

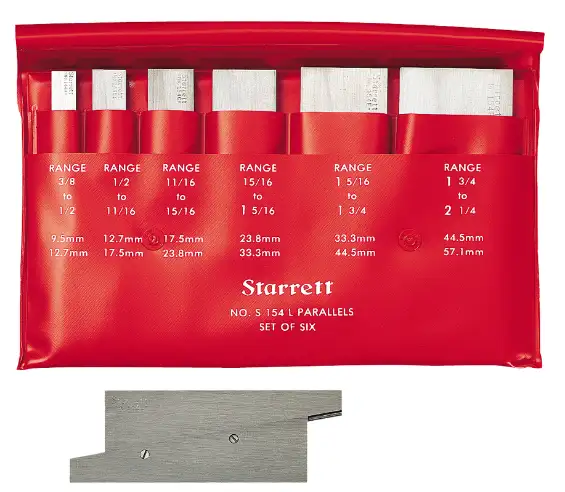

- Starrett S154LZ is a set of 6 adjustable parallels of A, B, C, D, E and F sizes.

- This parallel set has a parallelism of +/- 0.001 inches, ensuring precise alignment and maintaining accuracy.

- It has an adjustable feature that allows use in place of solid-type parallels.

- This adjustable parallel set has a thickness of 9/32 inches (7 mm).

- It offers a plastic pouch, providing a convenient storage solution and keeping the it organised, protected and easily accessible.

Frequently Asked Questions:

Q. How are Starrett S154LZ adjustable parallels set to the desired size?

A. Two faces of the parallels are slid against each other and set at the desired size setting using one or more set screws. Smaller-sized parallels (A, B & C) are locked using one screw, whereas larger-sized parallels (D, E & F) have two locking set screws.

Q. Is this Starrett S154LZ adjustable parallel set portable?

A. Starrett S154LZ adjustable parallel set comes in a plastic pouch for easy storage & transport.

Q. What is the measuring range of this Starrett S154LZ adjustable parallel set?

A. Starrett S154LZ adjustable parallels are available in lengths of 1-3/4, 2-1/8, 2-11/16 & 3-9/16 inches (45, 55, 70 & 90 mm). They have a measuring range of 3/8 to 1-5/16 inches (9.5 to 33 mm).

Q. Are there any special care instructions for maintaining the parallel set?

A. To ensure longevity, keep the parallel set clean & free from debris. Store it in the provided plastic pouch when not in use.

Q. What is the difference between the locking mechanisms for smaller and larger sizes?

A. Smaller sizes (A, B, C) are locked by one screw, while larger sizes (D, E, F) have two lock screws for added stability.

Q. What is the significance of the 0.001-inch parallelism standard?

A. The 0.001-inch parallelism standard ensures that the two parallel bars of each set maintain an accurate and uniform distance, enabling precise alignment.

Change Country

Change Country