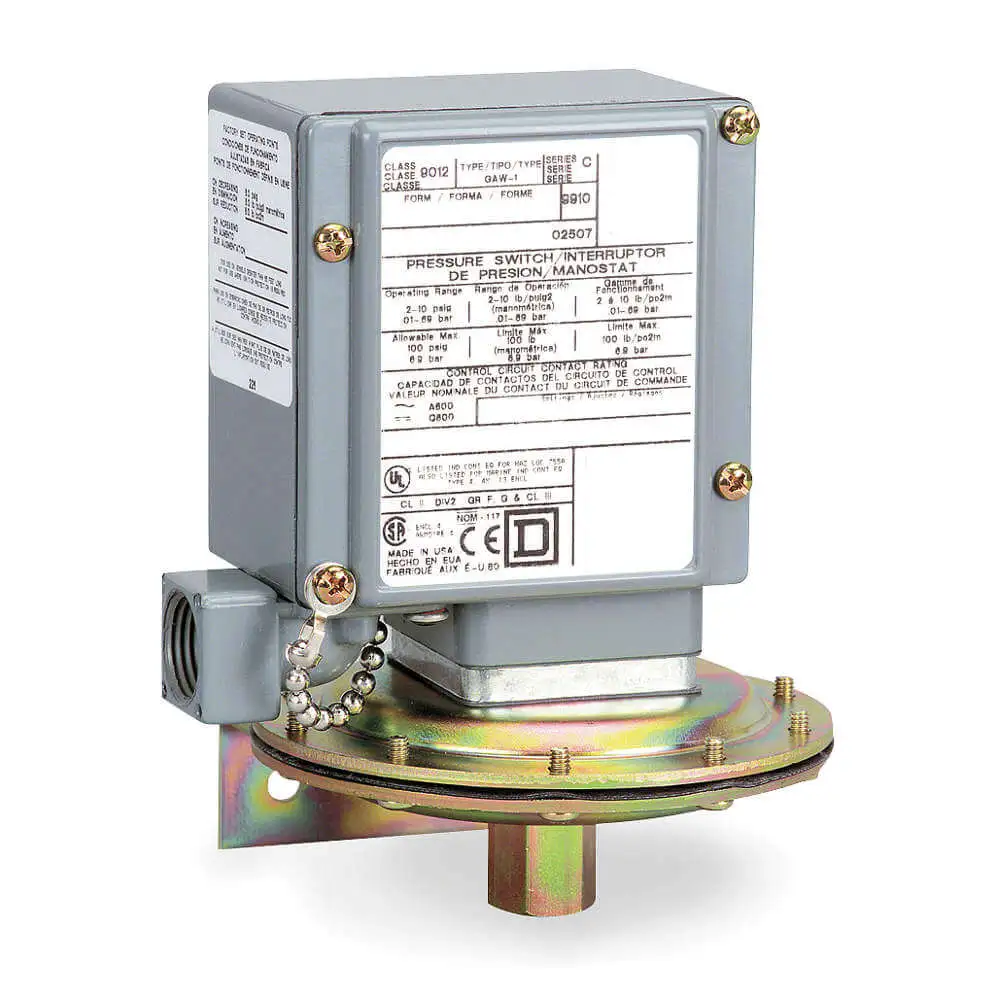

Square D 9012GAW5 pressure switch is ideal for pressure monitoring or controlling water in compressors, pumps, moulding presses, grinding machines, injection moulders, machining centres and special machines. It is used in industrial applications, such as compressed air systems, stamping presses, HVAC equipment, automatic grinders, chillers, welders and more.

Features:

- It features an aluminium enclosure to withstand high temperatures and offer structural rigidity.

- Square D 9012GAW5 pressure switch has a diaphragm actuator for optimum life and high speed of operation.

- This adjustable scale pressure switch has an adaptable differential scale for internal adjustments, enabling control of two distinct pressure thresholds.

- It offers an approximate adjustable differential pressure at a midrange of 6 to 30 psi and a maximum pressure of 475 psi for effectively handling varying pressure levels while maintaining accuracy.

- Customers looking for higher pressure range variants can opt the brand's 9012GQG2 piston pressure switch that can withstand differential pressures ranging from 90 to 2900 psi.

Compatible Accessories:

- Square D 9998PC268 Diaphragm Assembly: This diaphragm assembly is suitable to sense pressure for this pressure switch and transmit the mechanical movement to the internal components of the pressure switch.

Frequently Asked Questions:

Q. What is the operating temperature of this Square D 9012GAW5 pressure switch?

A. It has an operating temperature of -10 to 185 degrees F.

Q. What type of connection does this Square D pressure switch have?

A. It has screw clamp terminals for electrical connectivity and a 0.25-inch 18 NPTF connection for fluids.

Q. What is the life cycle of Square D 9012GAW5 pressure switch?

A. This pressure switch operates for 5000000 cycles at a rate of 120 cycles/min.

Q. How to maintain this adjustable scale pressure switch?

A.

- Periodically inspect the pressure switch for signs of wear, damage or corrosion. Check electrical connections for tightness and signs of overheating.

- Keep the surface of the pressure switch clean by removing dust and debris using a dry cloth or a soft brush. Avoid using water or cleaning agents that might damage the components.

- If the pressure readings seem inaccurate, calibrate the pressure switch by following the manufacturer's instructions.

- Ensure that the electrical connections are secure and free from corrosion. Tighten any loose connections to prevent voltage drops or interruptions.

- If your application's pressure requirements change, you might need to adjust the pressure settings on the switch.

- Ensure that the pressure switch is installed in an environment that aligns with its specified temperature and humidity ranges.

- Create a maintenance schedule based on the switch's usage and the manufacturer's recommendations. Regular maintenance helps identify potential issues before they escalate.

Change Country

Change Country