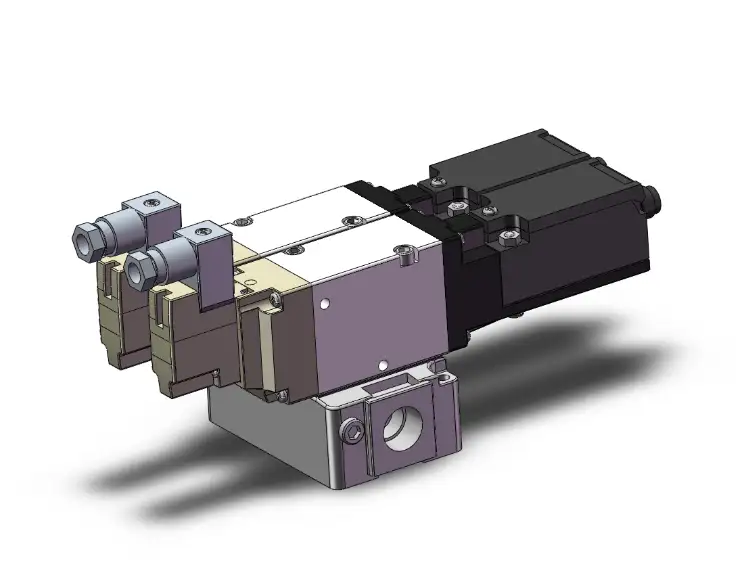

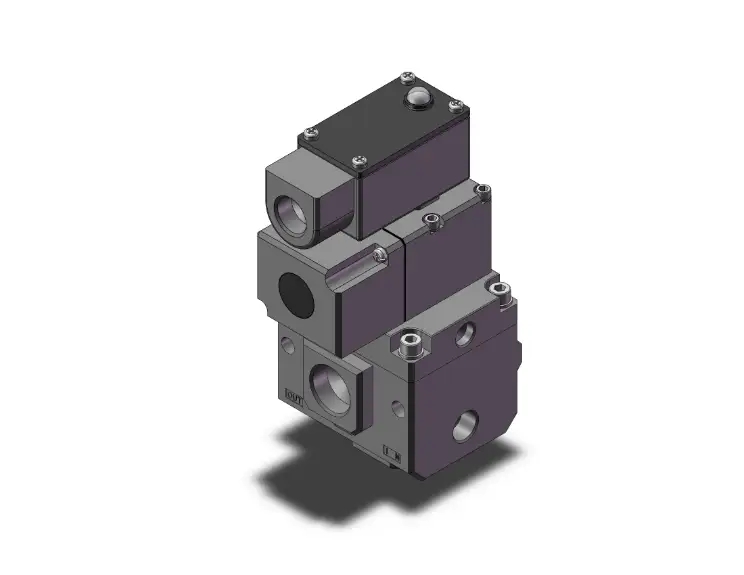

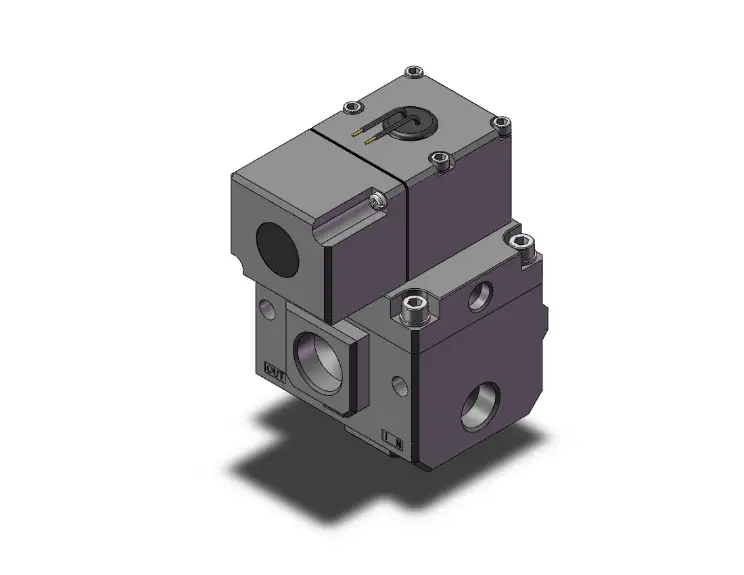

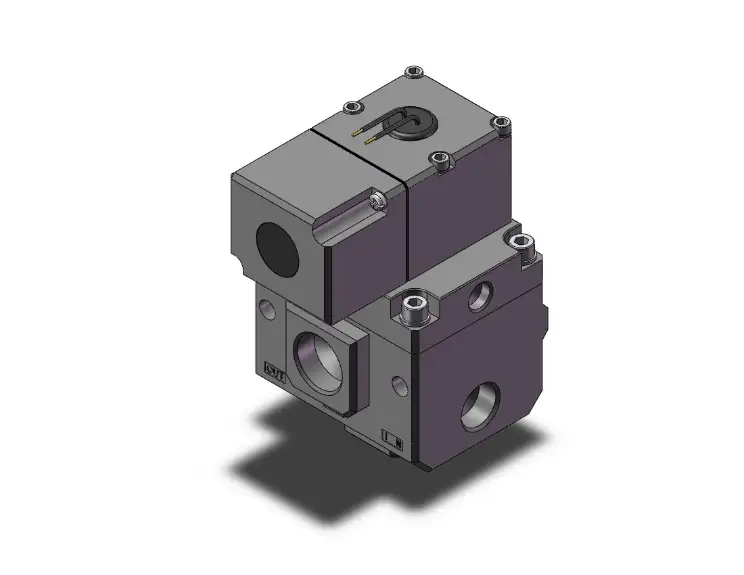

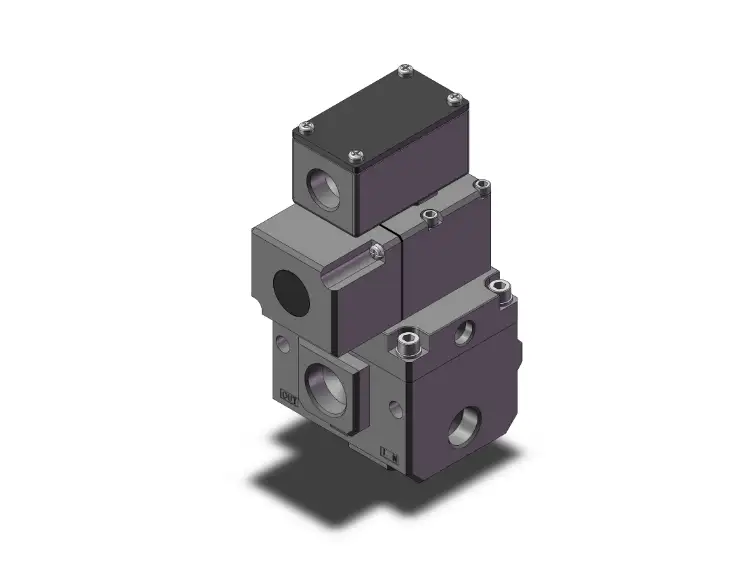

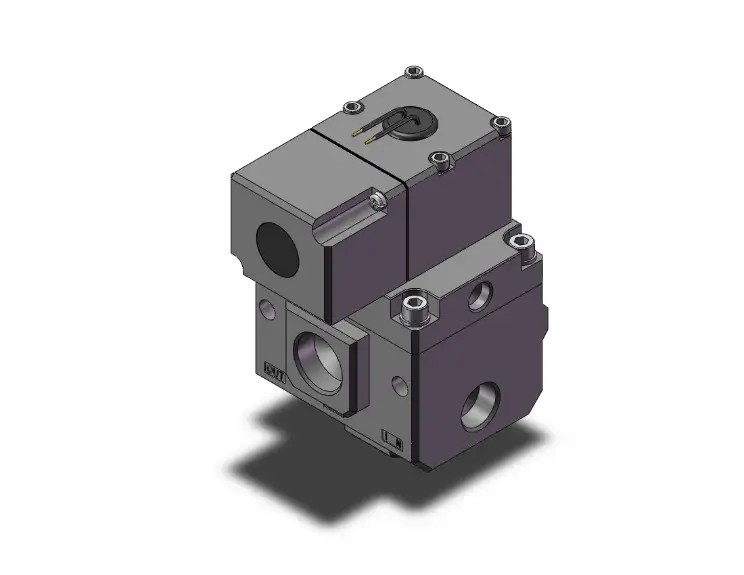

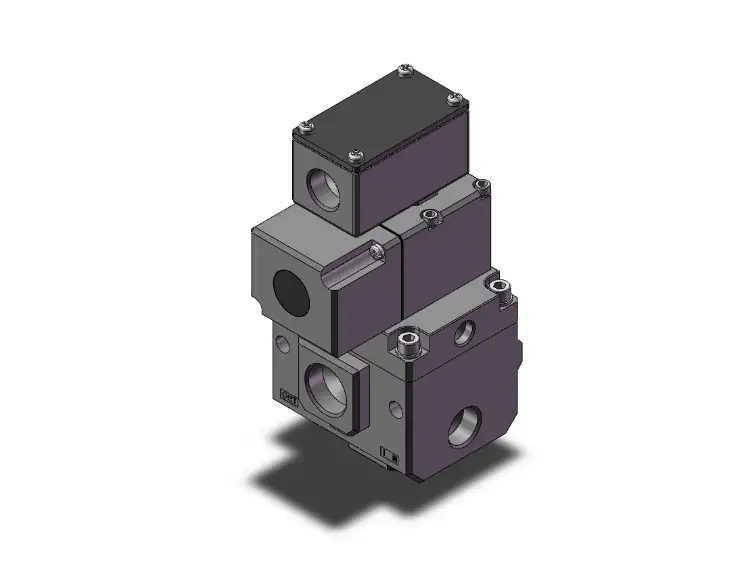

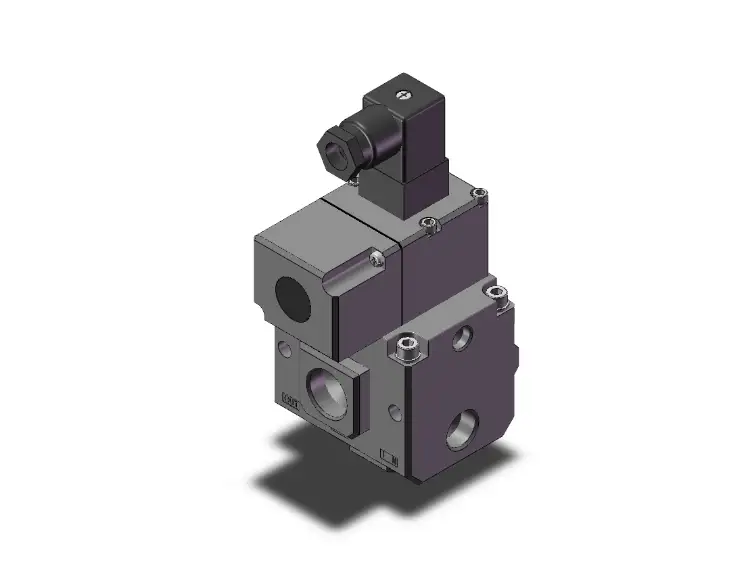

SMC VP544-5DZ1-03N-M-X538 solenoid valve is ideal for controlling the flow of fluids or gases in various applications. It operates by using an electromagnetic coil to actuate a plunger, allowing or blocking the flow through its ports. This 544-5DZ1-03N-M-X538 3-port, residual pressure release valve is used in manufacturing, automotive and process control applications requiring precise fluid control.

Features:

- This valve comes with a 3-port, pilot poppet type for precise fluid control in industrial automation and process control systems.

- It has a power-saving circuit designed to reduce power consumption, ensuring cost-effective and energy-efficient operation in industrial settings.

- This valve is available in port sizes, including 1/8 to 1/2 inches, providing flexibility to accommodate different flow rate requirements and system configurations.

- It offers Rc / G / NPT / NPTF thread type, making it compatible with piping systems & allowing for easy integration into existing setups or new installations.

Frequently Asked Questions:

Q. What is the difference between a fuse block and a fuse holder?

A. A fuse holder serves the purpose of mounting or holding a fuse. On the other hand, a fuse block not only keeps the fuses together but also connects them to the wiring systems.

Q. What is the default state of the valve when it is not powered?

A. The default state is closed, with the plunger blocking fluid or gas flow.

Q. How can I open the valve?

A. Applying an electrical current to the coil generates a magnetic field, attracting the plunger and opening the valve.

Q. What are the factors to consider while choosing the right solenoid valve for my application?

A. Major factors include fluid compatibility, pressure & temperature ratings, flow rate, electrical specifications, response time and environmental conditions.

Q. How do I maintain this SMC VP544-5DZ1-03N-M-X538 solenoid valve?

A.

- Disconnect power before performing maintenance.

- Regularly inspect and address any leaks around ports and connections.

- Periodically clean the valve's exterior to remove contaminants.

- Ensure secure and corrosion-free electrical connections.

- Replace worn components, such as seals or solenoid coils, as needed.

- Test valve operation to confirm proper functionality.

- Protect the valve from harsh environmental conditions as necessary.

Change Country

Change Country