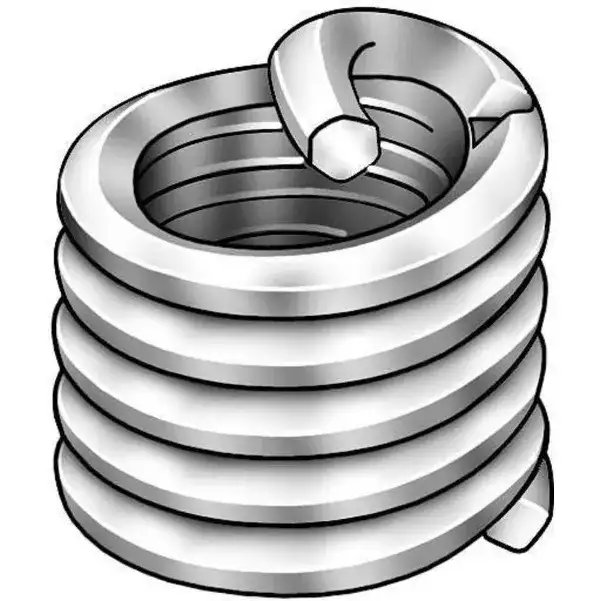

Helicoil A3585-4EN375 screw locking insert is used to install threaded fasteners in metals, polymers, wood & composite materials by repairing stripped / damaged tapped holes or creating secure threaded holes. It has Nitronic 60 construction for greater strength and wear resistance. It offers reduced downtime & maintenance costs and prevents loosening / rotational spinout of the attached fastener. This Nitronic 60 Helicoil locking insert is ideal for automobile, aerospace, electronics and maintenance applications.

Features:

- Helicoil A3585-4EN375 screw locking insert positively secures threaded fasteners using its resilient internal locking threads that grip the fastener like a bolt or screw, preventing loosening due to vibration or impact.

- These internal locking threads use self-locking torque on the fastener using a series of chords on one or more of the insert.

- This insert has a tang / prong at the end of its body for ease of installation.

- Its screw-lock allows regular removal & reassembly of the fastener without any major loss of torque.

- This Nitronic 60 Helicoil locking insert having a free size of 0.32 inches has 1/4-20 sized UNC internal thread with right-hand thread direction.

- Its Nitronic 60 construction has a tensile strength of 200000 psi and a rockwell hardness of C43-C50 for use in metallic materials.

Standards and Approvals:

- NASM 8846

- MA1565

- MIL-N-25027

Frequently Asked Questions:

Q. How to install this Helicoil A3585-4EN375 locking helical insert?

A.

- Drill out an appropriately sized hole in the material or remove damaged threading from an already prepared hole using a suitable drill bit.

- Use a tap / tapping tool to thread / rethread the hole in the material.

- Use an installation tool to wind the insert into the hole.

- Use a tang break-off rod or punch to remove the tang / prong and allow free passage of the fastener.

- Fasteners can now be installed into this Nitronic 60 Helicoil insert.

Q. Can this Nitronic 60 Helicoil locking insert be removed after installation?

A. Yes, this insert can be removed using a removal tool that unwinds it in the opposite direction than that used during installation. This locking helical insert allows assembly & disassembly of fasteners multiple times.

Q. Why are some thread inserts larger in diameter than the tapped hole before installation?

A. Selected thread inserts have a slightly larger diameter than the diameter of the tapped hole before installation, as the installation tool decreases the leading coil's diameter when it applies torque to the insert's prong / tang for easy installation. Once the threaded insert is installed, it acts like a spring and expands outward onto the material for strong anchoring.

€ EURChange Country

€ EURChange Country