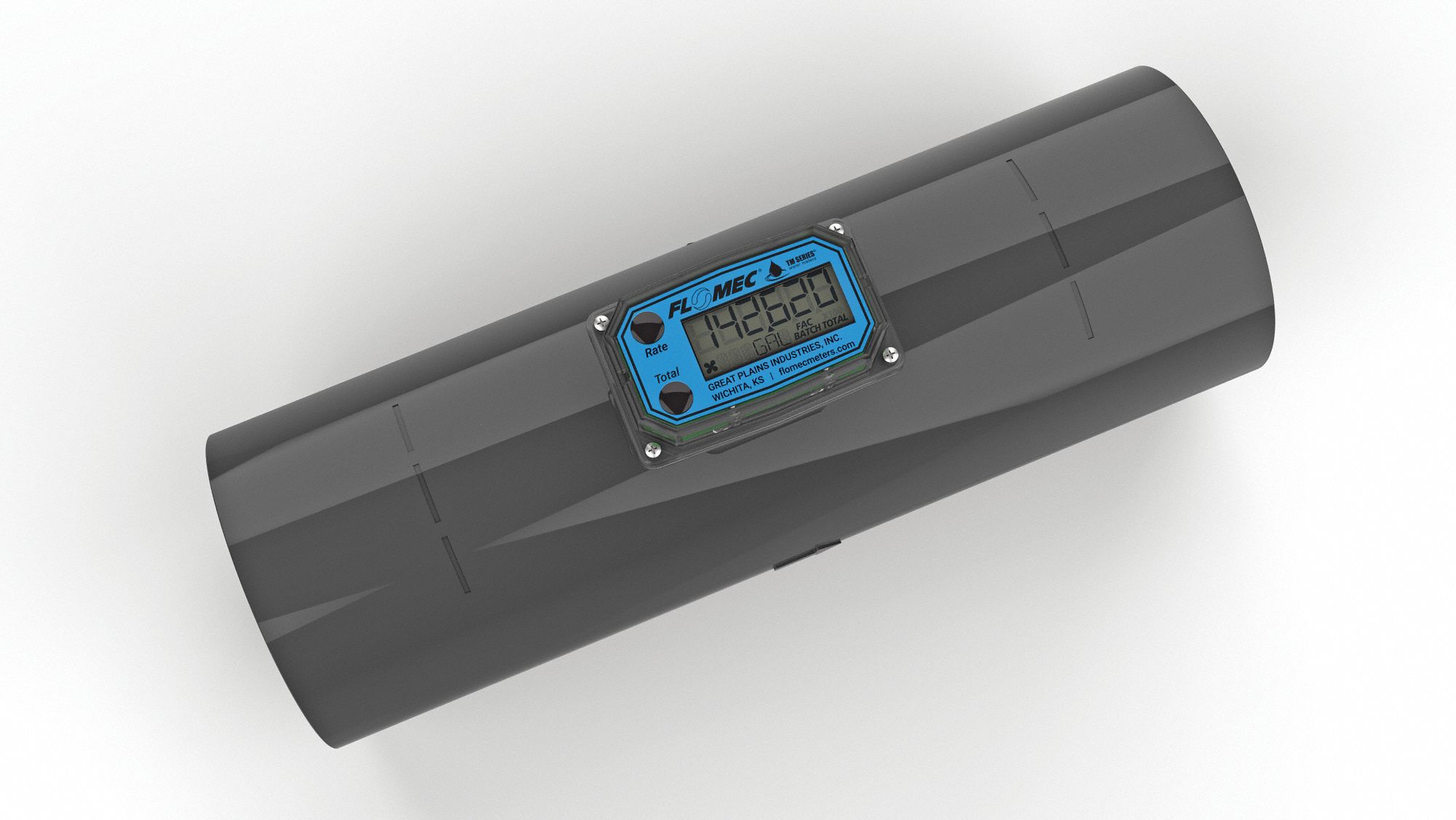

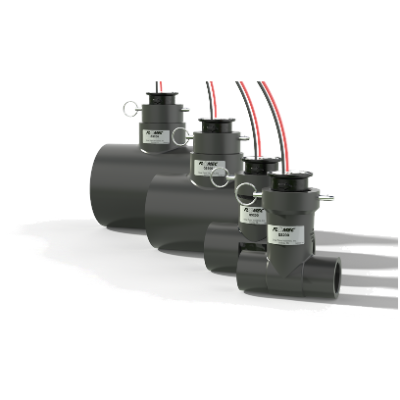

Flomec QS200 Insertion Ultrasonic Flowmeters

QS200 meter's Transit Time Technology does not require moving parts, allows low maintenance and has 2 wire connectors for power & pulse. They deliver prolonged stability and a broad measurement range, making ir possible to measure water usage and detect leaks. The LED light indicators turn green to indicate the functionality & basic power of the meter and amber for water flow of the meter.