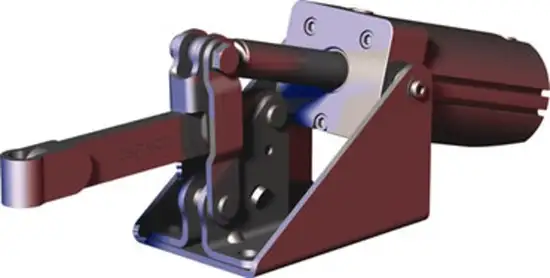

Destaco 810-SE pneumatic hold down toggle clamp is suitable for welding, gripping, clamping and locating applications. It is the pneumatic version of manual clamp models 210-U and 210-S. This pneumatic clamp holds products securely in place to ensure error free operation and is ideal for harsh welding environments that require superior clamping power for improved reliability & precision. Destaco 810-SE pneumatic hold down toggle clamp is made of stainless steel for structural rigidity and corrosion resistance on exposed surfaces. It requires a double acting pneumatic system for operation and comes equipped with a pneumatic cylinder having an input port for connecting to the compressed air source. This toggle clamp is equipped with hardened rivets & bushings at pivot points to fix, rotate & move the handle bar for the required work position. Destaco 810-SE pneumatic hold down toggle clamp can be operated at temperatures ranging from -14 to 194 degrees Fahrenheit and is capable of handling loads up to 750 lb. Destaco 810-SE pneumatic hold down toggle clamp can accommodate sensors designed to be mounted on cylinders, without grooves or tie rods in the cylinder body. These sensors are equipped with an LED for easy set up and can be operated at temperatures ranging from 14 to 140 degrees Fahrenheit.

Uses:

Destaco 810-SE pneumatic power clamp offers a broad combination of features, making it adaptable to applications such as gripping, clamping, system checking, fixturing, testing, welding, CNC machining and locating, in the aerospace, automotive and food & packaging industries.

Features:

- Destaco 810-SE pneumatic toggle clamp is the pneumatic version of 210 manual toggle clamp.

- This hold down clamp incorporates built in flow control for smooth operation and magnetic piston ring for position sensing.

- It comes with accurately machined steel components that feature hardened bushings & pivot pins.

- The sensor ready design accommodates either round or T-slot style sensors.

Compatible Accessories:

- Destaco 810CYL: These replacement cylinder assemblies are designed to replace faulty cylinders in case the old one wears out or is defective.

- Destaco 810169: These round reed switches feature a quick disconnect mechanism with an LED for easy set-up. These IP67 rated switches can be activated by a magnetic ring installed on the clamp's cylinder. They are designed to be mounted to cylinders with 4 mm round grooves.

- Destaco 8EA-109-1: These T-slot reed switches have a quick disconnect mechanism designed to be mounted to cylinders with T-slot grooves. They are IP67 rated and get activated by a magnetic ring installed on the clamp's cylinder.

Standards and Approvals:

- Destaco 810-SE pneumatic hold down toggle clamp conforms to international standards like ISO 14001:2015 & ISO 9001:2015 for ensuring environmental health & safety, and efficient performance of the clamp.

Installation:

- Destaco 810-SE pneumatic toggle clamp features threaded holes on the base plate to ensure easy and secure installation of the clamp to a smooth surface.

Frequently Asked Questions:

Q. How do you adjust a toggle clamp?

A. After clamping, the force can be adjusted by loosening / tightening the spindle nut.

Q. How to specify the right hold down clamp for a particular application?

A. The most important consideration is the size of the component that you're clamping, the amount of space available in the production process and what kind of access you need to have around the clamp. If you are clamping a very small component and you need to hold it close to the clamp, clearly a small clamp will be required. Secondly, one needs to consider the distance between the pivot point & the length of the clamp arm and the weight of the tooling. In addition, the user must also consider the amount of clamping force or holding force you need the clamp to apply.

Q. Why would you need a hold down toggle clamp?

A. Destaco hold down toggle clamps are designed for use in automated manufacturing processes where the requirement is to accurately clamp components repeatedly, quickly and accurately. They are ideal for applications where there is limited or no access to manually activate the clamp either because of space limitation (manual access isn't possible) or because the clamp is located remotely.

Q. Is it right to check the specifications?

A. By checking the specifications, you can ascertain the toggle clamp capacity, so it is a firm yes. The product specifications from the manufacturer consist of enough information about the throat depth and jaw opening. You can also ask our dedicated procurement team for an accurate guide.

Q. What does the clamp's holding capacity mean ?

A. The holding capacity or holding force is the capability of a clamp to hold down mechanical equipment or sheet metal while assembling automotive parts or during manufacturing processes.

Q. What does clamping force mean?

A. It is the amount of force actually applied to the workpiece by closing & locking the clamp, which is normally less than the stated holding capacity. The actual clamping force depends on various factors, including cylinder bore, cylinder area, spindle position (clamping arm length) and available air pressure. In most cases, the clamping force is approximately 2 to 3 times the force exerted by a pneumatic cylinder.

Change Country

Change Country