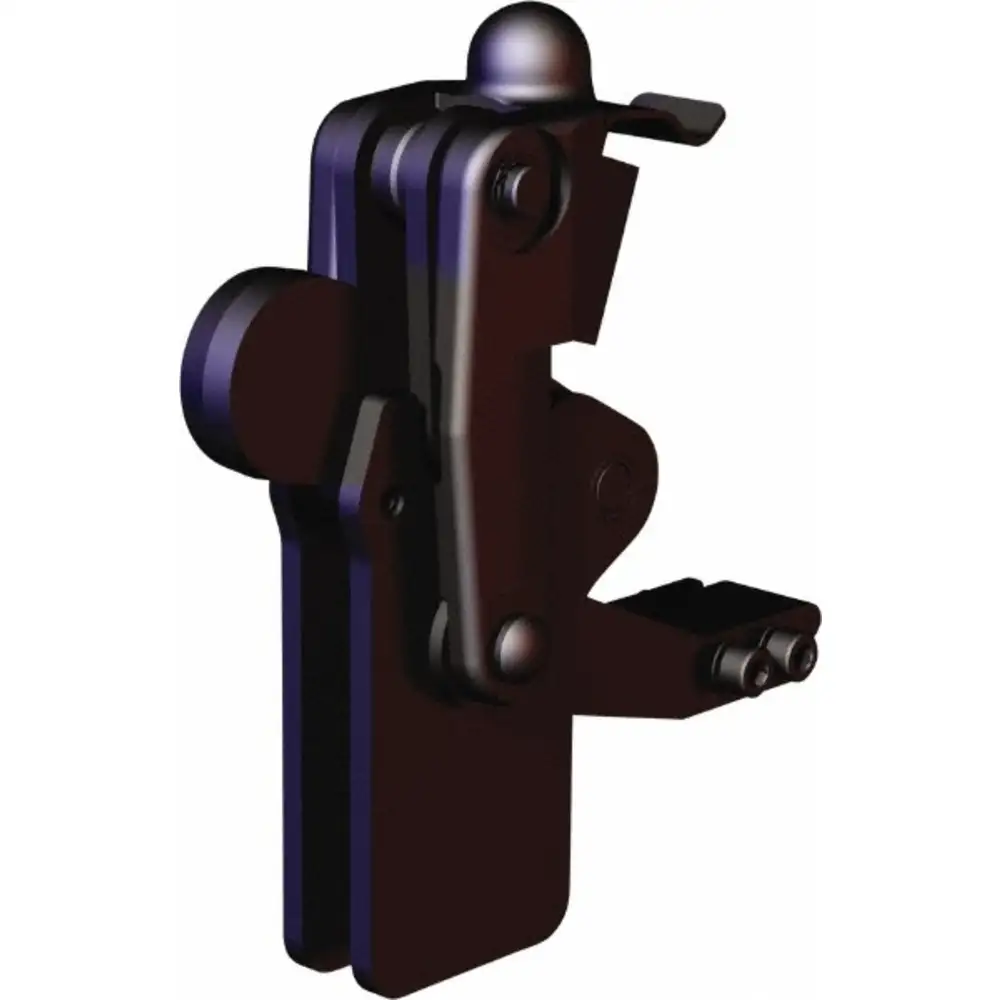

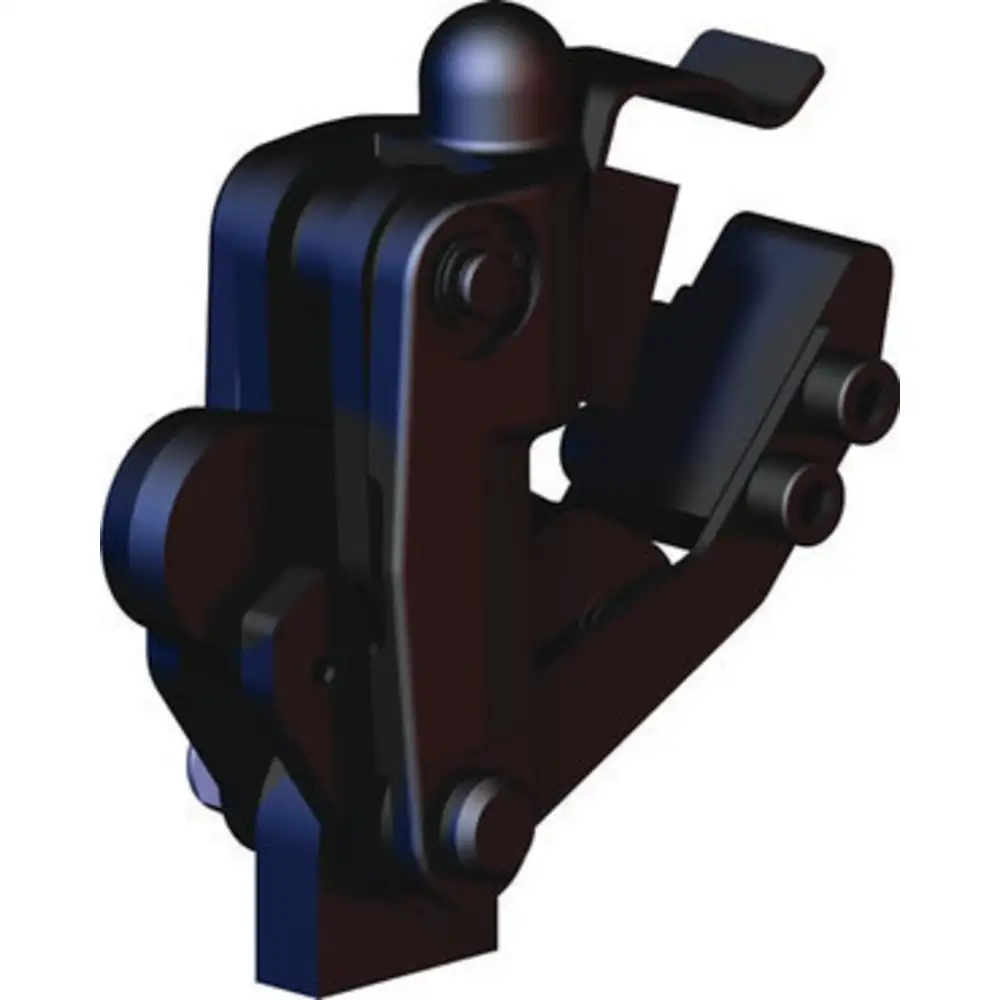

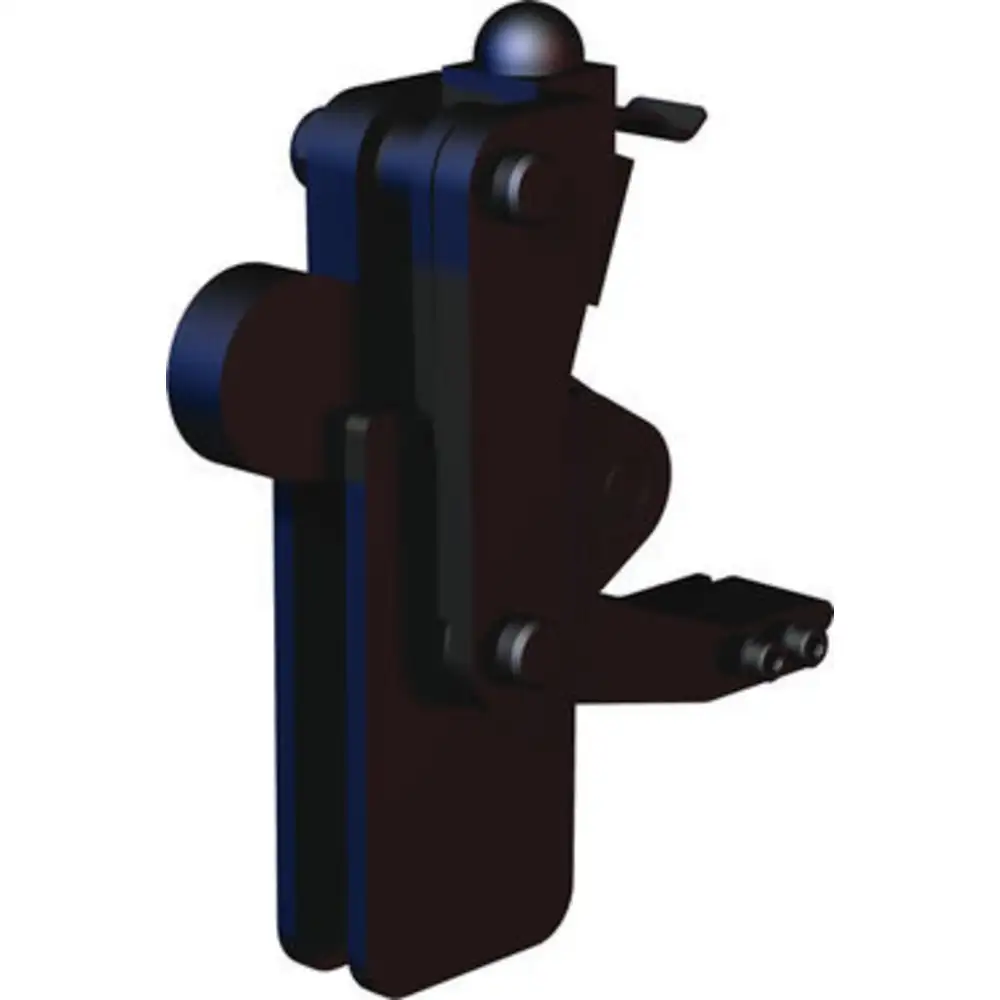

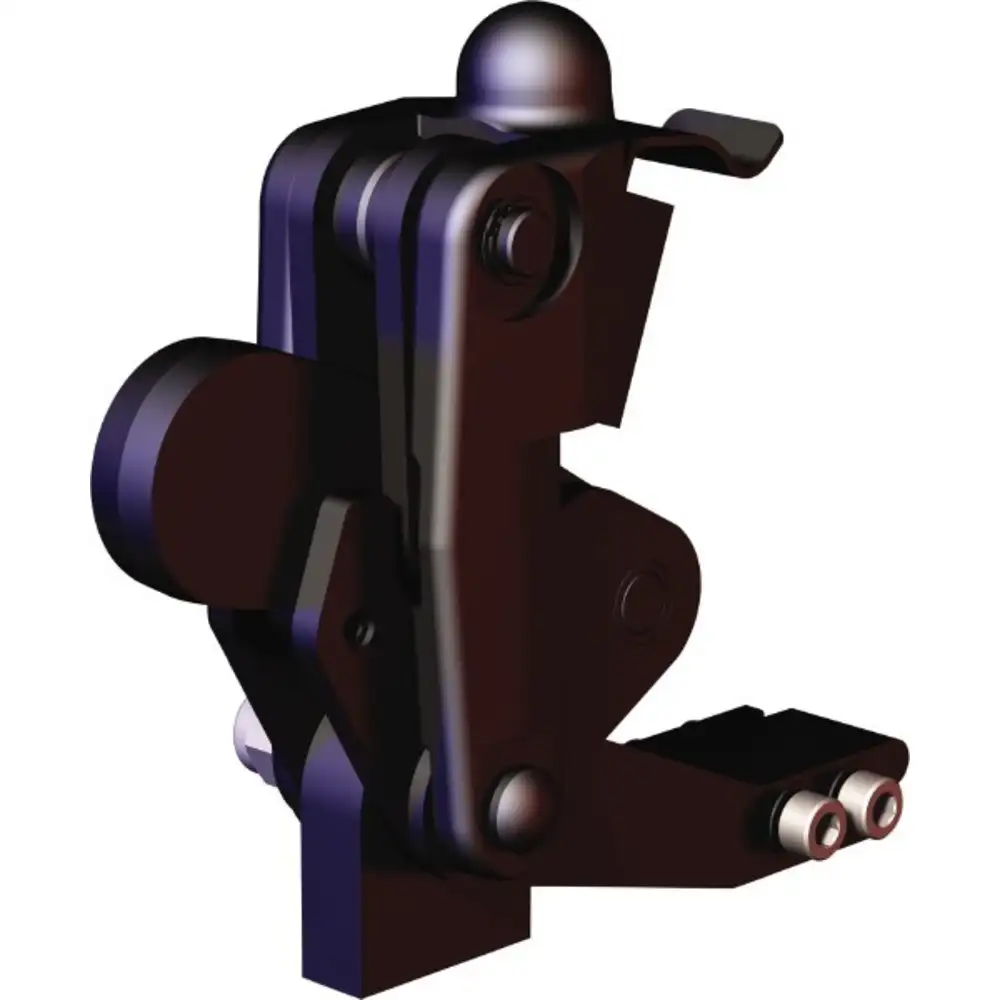

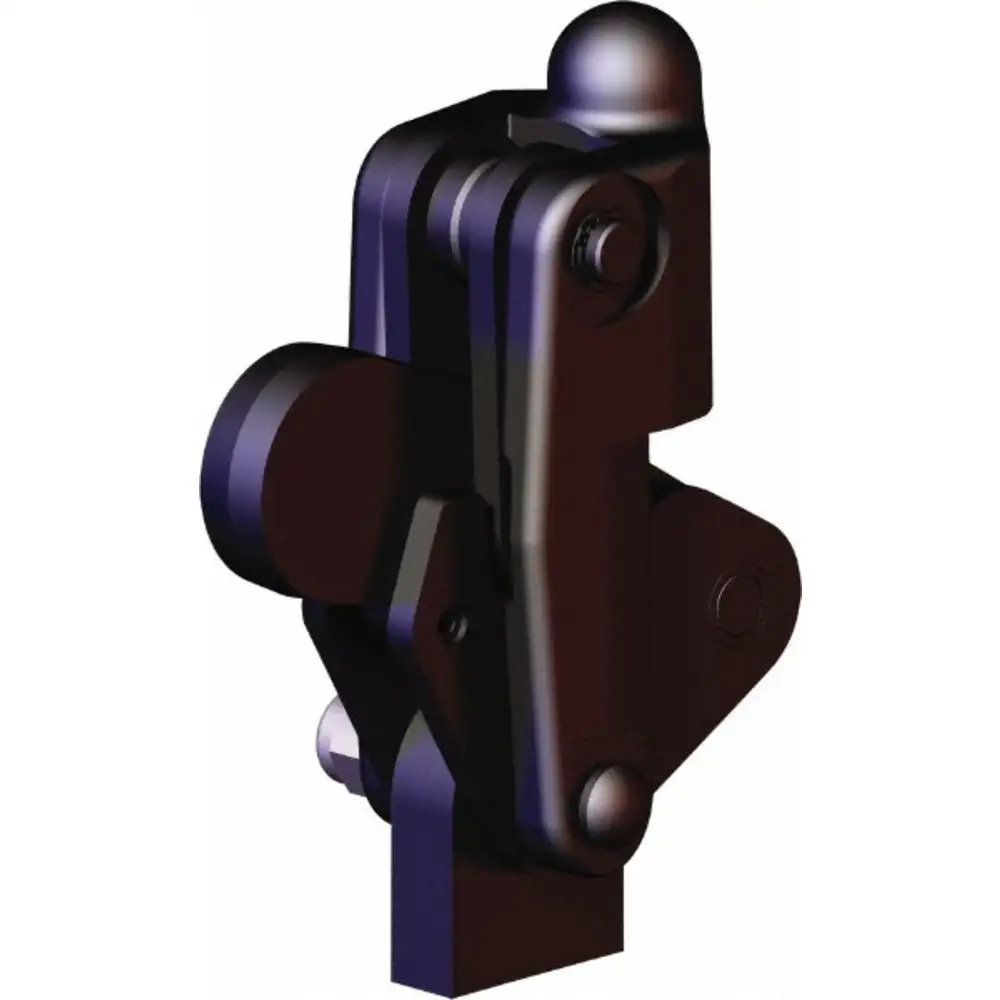

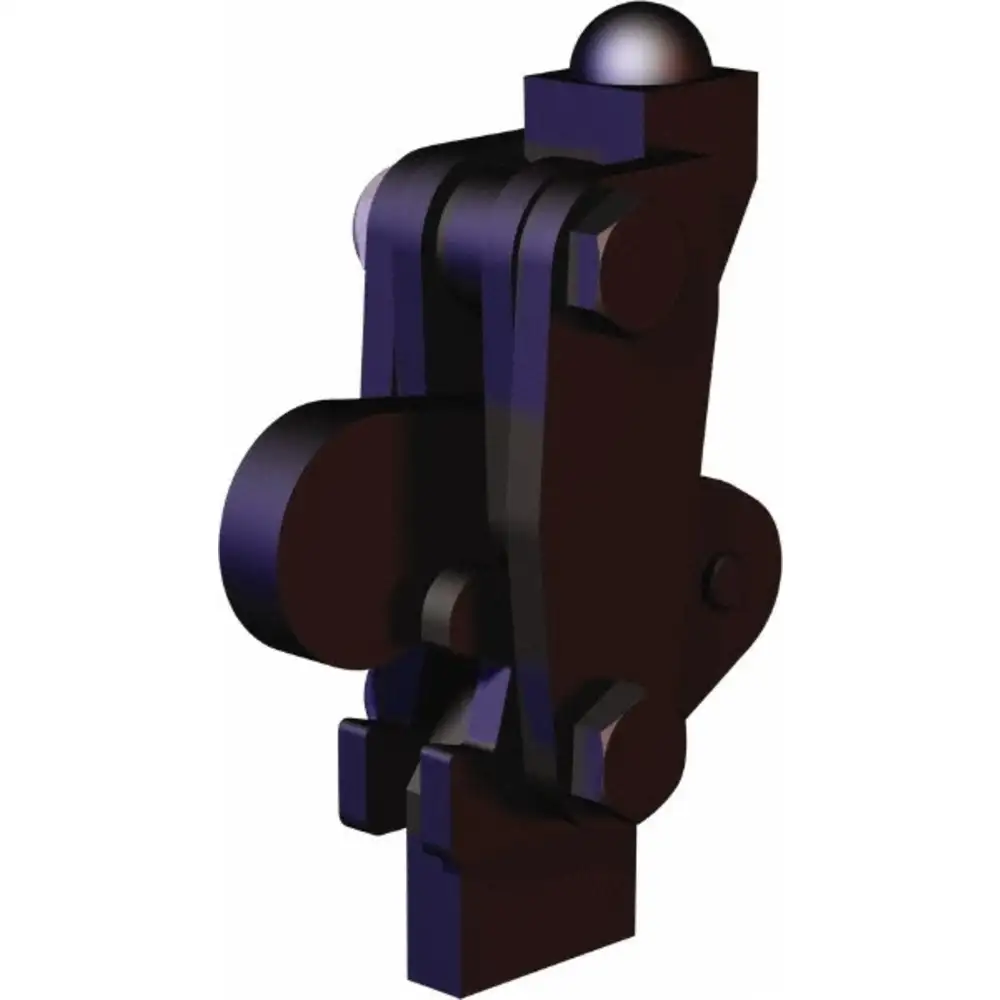

Destaco 505-MLBLSC weldable vertical hold down clamp is designed to apply downward clamping force by increasing the applied load via toggle mechanisms. It offers the flexibility to position the base, clamp arm & handle and weld them in the desired position to suit multiple applications. This clamp comprises accurately machined components having hardened and ground pivot pins and bushes. The clamp offers a stationary alternative to removable C clamps or spring clamps when securing material to a work surface. It holds workpieces in place using a lever handle that is pushed to the upright position when the clamp is engaged and is equipped with an ergonomically designed handle to minimise strain and pain while working. The lever handle engages & releases the clamping head, which holds a workpiece onto a worktable. This clamp features high clamping ability that reduces necessary fixtures for a particular application. Destaco 505-MLBLSC vertical hold down action toggle locking clamp is used in welding, assembling and heavy duty production applications in the aerospace, automotive and food & packaging industries. This clamp can adapt to workpieces of different heights and is virtually maintenance free, requiring only a few drops of lubricating oil to keep it in excellent condition. The vertical hold down clamp enables the user to undertake an action without being worried by the frequent movement of a workpiece. The unique pivot and lever system ensures maximum function and excellent performance. It has high exerting force and flexible adjustability that is useful when working with materials of varying thicknesses. This clamp features a fixed design to secure & loosen workpieces without moving the clamp itself and offers a locking spring clip design to secure the handle in the open position.

Uses:

Destaco weldable vertical hold down clamp (505-MLBLSC) offers a wide combination of features, making it adaptable to applications such as assembling, welding & heavy duty production in the aerospace, automotive and food & packaging industries.

Features:

- Destaco vertical hold down clamp (505-MLBLSC) has forged alloy steel construction to offer exceptional strength & structural rigidity and can handle loads up to 2475 lb.

- This clamp comes with hardened pivot pins and bushings to ensure long service life.

- The clamp offers a weldable clamping arm and bar that opens up to 200 degrees wide to clear the work area.

- It combines modular construction with a fixed design that offers the ability to secure and loosen material without moving the clamp.

- Destaco vertical hold down toggle clamp is available in a long base option for easy mounting.

- This model is supplied with a locking spring clip to secure the handle in the open position.

Compatible Accessories:

- Destaco 505503-L: This pipe handle is ideal for use with 505-MLBLSC vertical clamp for preventing accidents because of slipping or losing grip, to ensure high level of safety during work.

- Destaco 505502: The base plate enhances the capability of Detaco 505-MLBLSC vertical clamp. It is used to mount the clamp to a fixed square bar to meet the specifications of the application.

- Destaco 505501: The clamping bar is designed to be used with Destaco 505-MLBLSC vertical clamp that opens up to 200 degrees wide to clear the work area.

Standards and Approvals:

Destaco vertical hold down clamp 505-MLBLSC conforms to international standards like ISO 14001:2015 & ISO 9001:2015 for ensuring environmental health & safety, and quality performance of the clamp.

Installation:

- Destaco vertical hold down clamp 505-MLBLSC features a weldable design to allow the user to weld base, clamp arm & handle in any desired position for versatile clamp set up to meet different application requirements. We recommend welding the handles, clamp arms and mounting bases when disassembled. In addition, welding of non preheated parts may purely be done with the addition of welding fillers.

Frequently Asked Questions:

Q. How do hold down toggle clamps work?

A. Vertical handle toggle clamps actuate against the workpiece and compress or stretch the equipped linkages to keep the workpiece in a stationary position.

Q. What does holding capacity mean in terms of clamps?

A. The holding capacity or the holding force depicts the clamp's capability to hold down ]equipment or sheet metal on the assembly line or during other manufacturing processes.

Q. What is the benefit of using a toggle clamp over other types of clamps?

A. The main advantage of a toggle clamp is that it is quick-acting. These clamps can generate high holding force from the limited amount of force you put into the clamp. Depending on what you have been employing in the past, that efficiency will give a cost-benefit by accelerating production and increasing production outputs when you are able to increase the speed with which you are loading and unloading components.

Change Country

Change Country