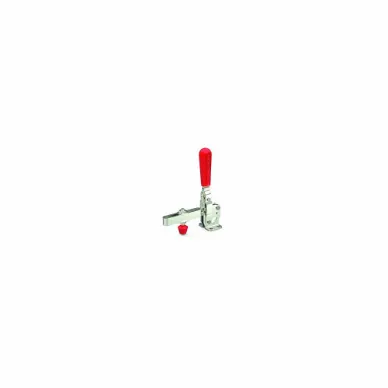

Vertical hold down clampsfeature a straight handle that is perpendicularly oriented to the base when in locked position. The movement of this handle push the clamping arm or the attached spindle against the workpieces for keeping them stationary throughout the operation while preventing it from loosening / slipping. These toggle clamps are an ideal choice for operations requiring repeated clamping / detaching of the workpiece. Destaco 207 Series vertical hold down clamps are used to hold workpieces against flat surfaces for woodworking, light machining, fixture checking & closure operations. 207 Series toggle clamps offer the largest selection of arms (U bar, long U bar, open U bar, solid bar & long solid bar) and mounting (flange base, straight base & dual base) options for use in diverse applications. Destaco 207-UL manual toggle clamp has steel construction for structural rigidity and minimising damage / wear due to abrasive conditions. It features a long U bar that extends the reach of the clamp and allows spindle adjustment for decreasing downtime and preventing buying of a separate clamp to handle workpieces with varying thicknessess. This clamp has a flanged base with threaded mounting holes for quick installation on a flat, horizontal surface / workpiece. Raptor Supplies also offers these clamps in variants having stainless steel construction, Toggle lock Plus feature and T handle for ease of use in applications with varying requirements.

Uses:

- This Destaco 207-UL vertical hold down clamp is ideal for assembly & testing, checking fixtures, light machining and woodworking operations in the aerospace, consumer goods, transportation, automotive and food & packaging industries. It can also be used for holding and closing lids, chamber doors, covers and access doors.

Features:

- Destaco 207-UL vertical hold down clamp comes with a neoprene spindle, providing a maximum load capacity of 375 lb.

- It has steel construction for strength, durability and preventing bending / breaking under heavy loads.

- This clamp has flanged base for easy installation on flat surfaces / workpieces.

- It has long U bar for extending the reach of the clamp and enabling spindle adjustment along the holding bar length, thereby accommodating various sized workpieces.

- This clamp is equipped with a straight vertical handle that rotates 57 degrees to open the clamp bar 99 degrees.

- It has a brightly coloured plastic handle that ensures easy gripping and minimises user fatigue over prolonged use.

- This clamp has a height of 1.25 inches and clamp arm length of 3.85 inches.

Compatible Accessories:

- Raptor Supplies delivers Destaco 225208-M flat tip bonded neoprene spindle for holding workpieces.

- Destaco offers replacement parts and accessories for Destaco 207-UL manual clamp like flanged washer (507107) for secure attachment of spindle and flanged grip (207305) for secure holding of the clamp handle.

- Destaco 207426-Q cross arm set can also be attached to the clamping arm for accommodating two spindles at the same time.

Standards and Approvals:

- Destaco 207-UL vertical hold down clamp is manufactured in compliance with ISO 9001:2015 & ISO 14001:2015 industry standards for environmental health, safety and superior performance of the clamp.

Installation:

- Destaco 207-UL hold down clamp is mounted to the workpieces or flat surfaces using two pairs of threaded holes on the base for secure installation.

- If the clamp is required to be removed, it can be easily unscrewed using a simple screwdriver.

Frequently Asked Questions:

Q. What other variants of Destaco 207-UL clamp are available on Raptor Supplies?

A. In addition to this variant having flanged base & long U bar, Destaco also offers straight base, long U bar (Destaco 207-ULB) and flanged base, long U bar & T handle (Destaco 207-TUL) style vertical clamps as well. For more variants related to Destaco 207-UL clamp, visit Destaco 207 Series clamps page on our website.

Q. What does holding capacity mean in terms of clamps?

A. The holding force or the holding capacity depicts the clamp's ideal capability to hold down the equipment or sheet metal on assembly lines or during other similar industrial operations. It is measured during the clamp manufacturing process.

Q. What is the difference between a vertical & horizontal toggle clamp?

A. The difference lies in the orientation of the clamp handle when the clamp is in the locked position. A vertical clamp handle is vertically oriented (perpendicular to the base) when in locked position, while in the case of a horizontal toggle clamp, it is horizontally oriented (parallel to the base).

Q. How do vertical hold down clamps work?

A. U bar style clamps, such as Destaco 207-UL, feature a flat tip bonded neoprene spindle that is manually operated using a handle / lever. This handle movement pushes the spindle against the workpiece and prevents it from moving mid operation, thereby ensuring secure clamping.

Change Country

Change Country