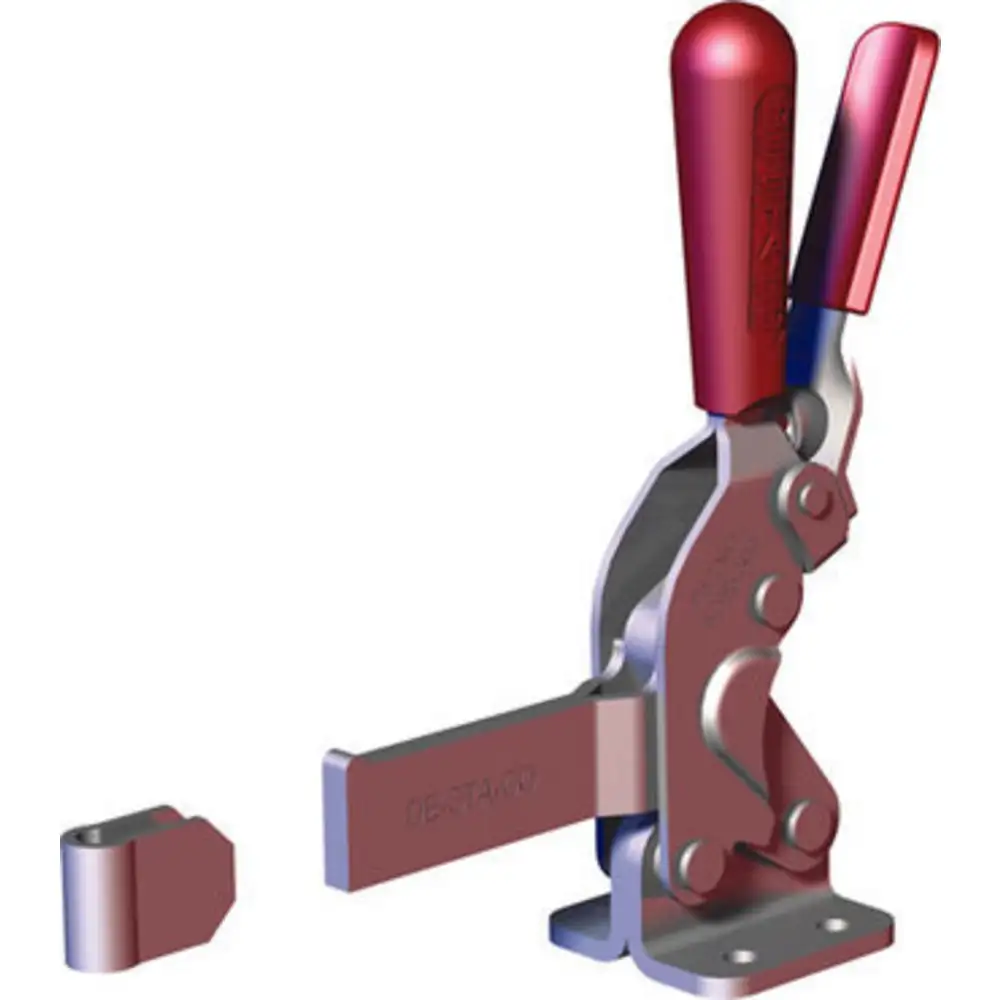

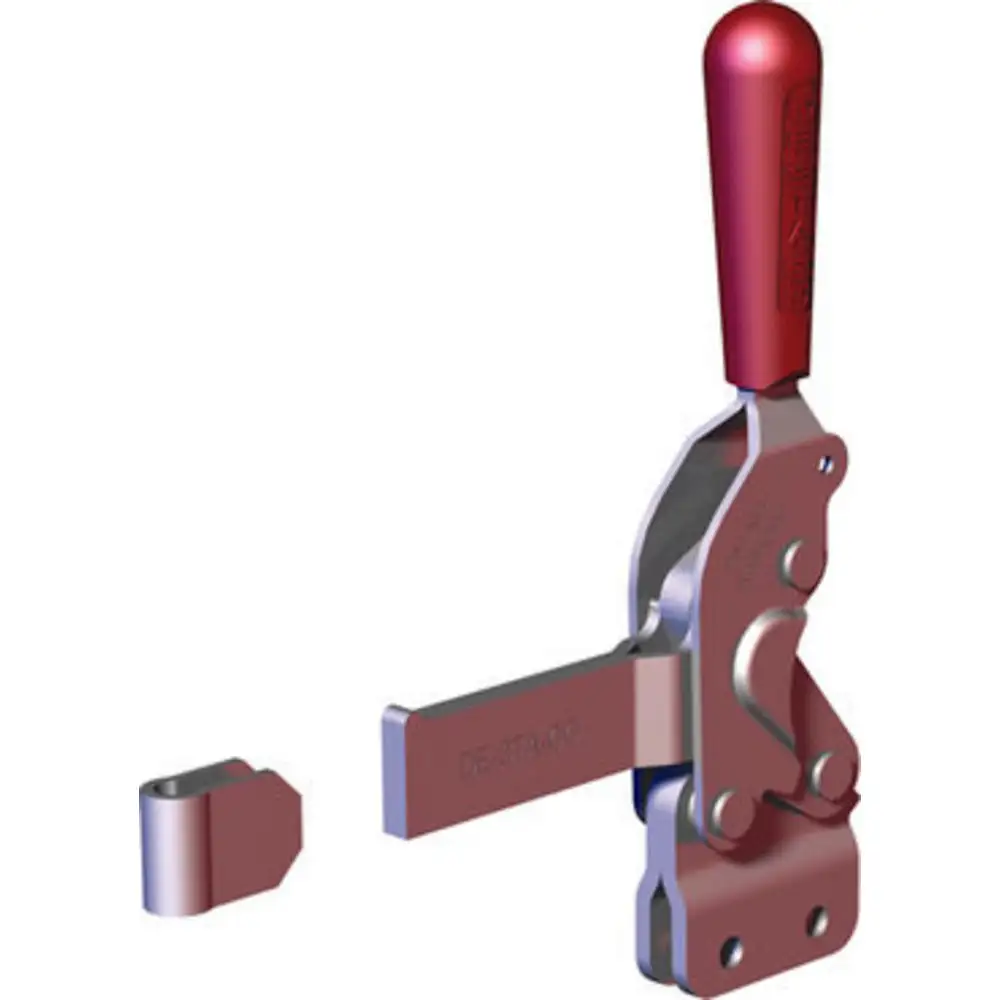

Destaco 2010-SR vertical hold down clamp is suitable for holding down workpieces against flat surfaces / workbenches. This toggle clamp is a suitable choice for operations where there is a requirement to clamp / detach the workpiece repeatedly throughout the operation. Its long clamping arm & spindle contacts the workpiece in near vertical position for transferring maximum clamping force during operation while preventing it from loosening / slipping. Destaco vertical toggle clamp has carbon steel construction which is zinc plated for minimising damage / wear against abrasive conditions & outdoor environments. This clamp is designed for ensuring a long life cycle when using standard clamping arms and spindles. It features a long handle that ensures maximum hand clearance while clamping the workpiece for providing safety during operation. Destaco vertical hold down clamp comes with the Toggle Lock Plus feature which includes a locking release lever for ensuring that the over centre locking condition is maintained throughout the operation. This mechanism prevents the clamp from accidentally unlocking mid operation. This toggle clamp has hardened bushings at key pivot points for delivering maximum durability. However, this clamp is not recommended for machining applications. Destaco 2010 Series clampsare also offered in straight base U bar and flanged base U bar variants on Raptor Supplies.

Uses:

- Destaco 2010-SR vertical hold down clamp is designed for various commercial tasks including checking fixtures, woodworking, light machining and assembly & testing applications.

Features:

- Destaco 2010-SR vertical hold down toggle locking clamp's long clamping arm & spindle contacts the workpiece in near vertical position for transferring maximum clamping force during operation while preventing it from loosening / slipping.

- The carbon steel construction of this toggle clamp provides rigidity during operation & the zinc plated finish ensures abrasion resistance.

- This Destaco vertical hold down toggle locking clamp comes with Toggle Lock Plus feature which includes a locking release lever for ensuring that the over centre locking condition is maintained throughout the operation.

- This toggle clamp has hardened bushings at key pivot points for delivering maximum durability.

- Destaco 2010-SR vertical hold down toggle locking clamp's bright coloured plastic handle ensures easy gripping and minimises user fatigue over prolonged use.

- Its flanged style base features two pairs of mounting holes; screws can be used to fasten the clamp on a flat surface / workbench.

- Destaco vertical hold down clamp features a solid clamping bar that is designed for preventing the workpiece from slipping or moving mid operation.

- Destaco also offers a wide variety of vertical hold down clamps in a range of configurations & styles like J hook style clamping arms, low profile T style handles & Toggle Lock Plus enabled clamps.

Compatible Accessories:

- Destaco 2010115-E bolt retainer: It is used to secure / hold the spindle assembly in place for Destaco 2010-SR vertical hold down clamp.

Standards and Approvals:

- Destaco 2010-SR vertical hold down clamp is manufactured in compliance with international industry standards like ISO 9001:2015 & ISO 14001:2015.

Installation:

- Destaco 2010-SR vertical hold down clamp has a flanged base mounting style for enabling secure installation on flat surfaces / workbenches. Upon requirement, due to its flanged base, this straight line action clamp can be easily removed as well.

Frequently Asked Questions:

Q. Does the brand offer vertical hold down clamps in other base mounting styles?

A. Yes, in addition to Destaco 2010-SR flanged base solid bar variant, the brand offers straight base U bar (Destaco 2010-UB) and flanged base U bar (Destaco 2010-U) vertical clamps as well.

Q. What is the difference between a vertical & horizontal toggle clamp?

A. The difference lies in the orientation of the clamp handle when the clamp is in the locked position. A vertical clamp handle is positioned vertically (perpendicular to the base) when in locked position, while in the case of a horizontal toggle clamp, it is positioned horizontally (parallel to the base).

Q. What does holding capacity mean in terms of clamps?

A. The holding force or the holding capacity depicts the clamp's capability to hold down equipment or sheet metal on assembly lines or during similar manufacturing processes.

Q. What is a vertical hold down clamp?

A. Destaco vertical hold down clamps are specially designed for holding the workpiece stationary against a flat surface / workbench for various industrial applications like woodworking & metalworking.

Q. What does clamping force mean?

A. Clamping force is the amount of force actually applied to a workpiece by closing & locking the clamp. It is normally less than the stated holding capacity. The actual clamping force depends on various factors, including cylinder bore, cylinder area, spindle position (clamping arm length) and available air pressure. In most cases, the clamping force is approximately 2 to 3 times the force exerted by a pneumatic cylinder.

Q. How do vertical hold down clamps work?

A. Some U bar style clamps like Destaco 2010-SR feature a solid style clamping arm that is manually operated using a handle / lever. This handle movement pushes the spindle against the workpiece and prevents it from moving mid operation, thereby ensuring secure clamping.

Q. Which grease is recommended for use with Destaco clamps when rebuilding?

A. Whenever you're dealing with the brand's mechanical clamps, it is recommended to use a coupling grease like Mobil XTC.

Q. Are Destaco clamps rust resistant?

A. Yes, carbon steel clamps from Destaco are zinc plated for withstanding & minimising wear against harsh industrial environments. For applications that require clamping in outdoor conditions, stainless steel variants are also available.

Change Country

Change Country