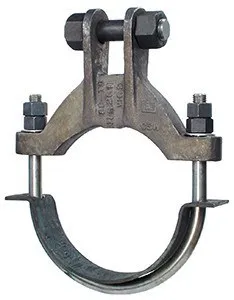

Anvil FIG 295A pipe clamp is ideal for preventing pipe movement and vibration, ensuring the stability and integrity of fluid-carrying systems. It helps mitigate the risk of damage, leaks and potential structural issues by firmly anchoring pipes and providing vital support. It supports and securies pipes, tubing and conduits in plumbing, HVAC and mechanical systems in various industrial, commercial and construction applications.

Features:

- It features high-strength (chrome molybdenum alloy steel) construction for exceptional durability and resistance to deformation even under heavy loads.

- This pipe clamp has plain finish, enhancing its resistance to corrosion for use in a wide range of environmental conditions.

- The pipe clamp offers grade 22 strength, ensuring it can handle substantial loads with a load capacity of up to 745 pounds, providing robust support for pipes and conduits.

- It has a maximum temperature rating of 1050 degrees F to and maintains structural integrity & performance in high-temperature industrial environments.

Frequently Asked Questions:

Q. How do I clean and maintain this Anvil FIG 295A pipe clamp for long-lasting performance?

A. Proper maintenance involves periodic inspection for signs of corrosion or damage, particularly in corrosive environments. Regular cleaning with a wire brush and applying an anti-corrosion coating will help extend its lifespan.

Q. What factors should I consider when selecting the appropriate size and load capacity for my pipe clamp installation?

A. Major factors include the size and weight of the pipes or conduits, the distance between supports and the nature of the load (static or dynamic). Accurate calculations based on these factors are essential for ensuring proper support.

Q. Is there any specific guidance for the installation of Anvil FIG 295A double bolt pipe clamp?

A. Proper installation requires precise alignment with the pipe or conduit and secure fastening using the provided bolts. Adequate tightening without over-torquing is essential to prevent deformation of the clamp or the supported pipes. Follow manufacturer recommendations for best results.

Change Country

Change Country