Uses

Norton Abrasives diamond & CBN grinding wheels are designed for cutting and smoothing hard materials for metalworking, aerospace, mining, fabrication, construction, instrumentation and manufacturing applications. These grinding wheels ensure minimum thermal damage inflicted to the workpiece while cutting. They also ensure high precision while performing the workpiece cutting. Diamond & CBN grinding wheels are ideal for sharpening cemented carbide cutting tools, cutting off ceramic & glass materials, surface grinding dies, cutting off carbide rods, grinding spray coatings and steel parts. Various materials that can grind with these wheels are electronic components, abrasives, stones, plastics, fibreglass, ceramics and glass.

Features

Diamond and CBN grinding wheels have high quality synthetic diamond / CBN (cubic Boron Nitride) abrasive material for ensuring high precision while cutting hard materials. These grinding / cutting wheels deliver high material removal rates and can easily cut difficult to grind steel parts. These grinding wheels are wear resistant and are thermally stable.

Working Mechanism

Diamond cutting wheels have a metal wheel having a diamond coating on its cutting edges. Similarly, CBN grinding wheels have a lair of synthetic material on their cutting edges. These cutting wheels are fixed onto a grinding machine for grinding & slicing hard materials.

Frequently Asked Questions

How to select a grinding wheel?

Various factors contribute for selecting the grinding wheel type that are mentioned below:

- Material being ground: Aluminium oxide grain wheels are used for grinding ferrous metals, silicon carbide grain grinding wheels for non ferrous metals and non metals and ceramic & super abrasive grains are used for either of these workpiece materials.

- Grinding pressure: The grinding pressure in the grinding zone also determines the type of suitable grinding wheel. For heavy pressure applications, the user should use tough / durable grain wheels that tolerate a large amount of pressure generated during the grinding operation.

- Form accuracy and required finish: Finer grit grinding wheels should be used for achieving close geometric tolerances. For applications that require fast stock removal rates, coarse grit wheels are an ideal choice.

- Area of contact: If a small area of contact is needed, the user can choose tough / durable grain grinding wheels. As it equates to higher force per grain, the wheel material should be highly durable.

- Machine / spindle horse power: When the grinding machine has higher horsepower available to the spindle, the user should install a harder wheel grade grain. For low horsepower machines, softer grain wheels should be used to prevent the grinding wheel grain from dulling and causing surface damage to the workpiece.

When to replace Norton Abrasives grinding wheel?

It depends upon the grinding wheel type and the application.

- Straight wheels: The usable portion of the straight style grinding wheel is considered to be the portion that extends beyond the mounting flanges. The grinding wheel should not be worn to the size that would allow the flange assembly to touch against the workpiece holding fixture or the workpiece itself.

- Cylinder wheels and segments: These wheels are fixed onto grinding machines and these machines determine the discard size of these wheels. The down feed mechanism of these machines keeps the grinding wheel from contacting the workpiece. The grinding wheel should not be lowered for avoiding wheel breakage.

- Recessed wheels: These wheels have recesses that cannot be worn down to the mounting flange as the edge of the recess spalls away. Additionally, wheel grit size and application counts while replacing these cylinder wheels.

- Portable wheel cups: Norton Abrasives portable wheel cups must be discarded as the machine guard prevents the proper grinding of the workpiece. The machine guard determines the discard size by preventing any additional grinding to the wheels rim.

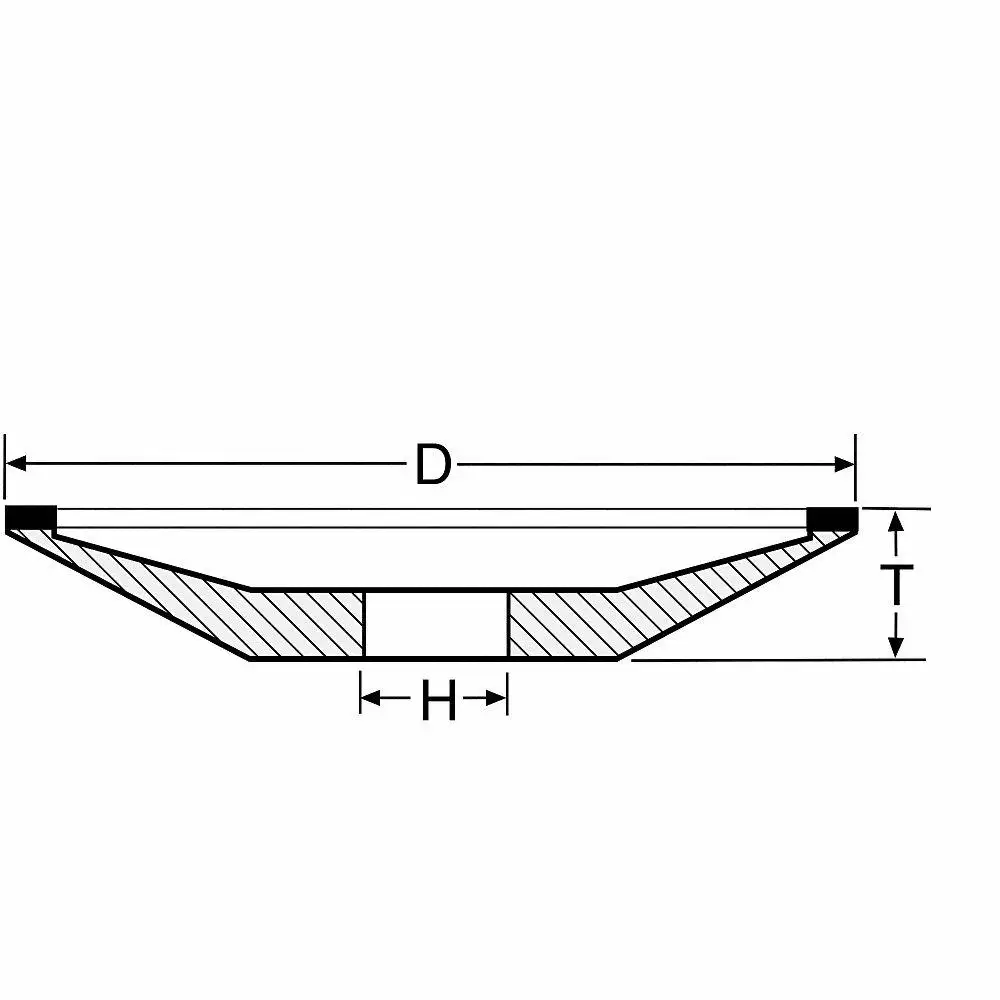

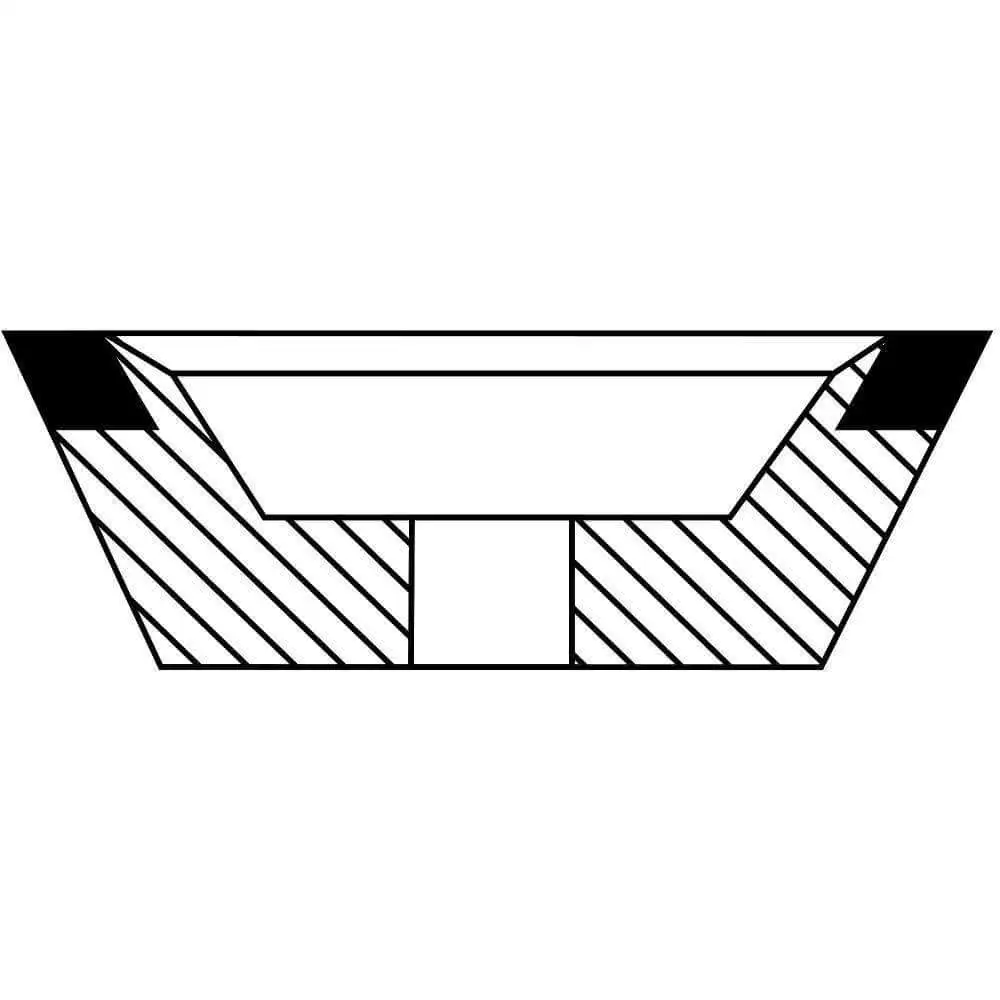

- Raised hub wheels: Norton Abrasives raised hub wheels are gauged based on machine guard as well. If the application in hand allows the grinding wheel to be worn stub, the user should halt before contacting the wheel mounting flanges. Additionally, the wheel's hub should not be used for grinding.

Why grinding wheel dressing should be done before mounting the grinding wheel?

Dressing the grinding wheel refers to removing the current layer of abrasive material so that a sharp surface is achieved for working on the workpiece. Trueing the grinding wheel makes the workpiece grinding surface parallel to other reference planes or grinding tables, so the grinding wheel is even from all sides and produces an accurate surface.

Can CBN grinding wheels grind carbide?

Yes, CBN grinding wheels can sharpen pure carbide bits. A wet CBN grinding wheel can slice through the carbide material at the same speed as the diamond wheel. However, while cutting carbide materials, CBN wheels wear at faster rates.

What are the uses of CBN grinding wheels?

CBN grinding wheels have high chemical resistance and thermal stability, which makes these grinding wheels suitable for grinding ferrous materials like bearing & hardened steel, nickel-based alloys and ferrous materials. These grinding wheels are used for cutting, sharpening and removing metal from hard surfaces.

What is grit size in Norton Abrasives grinding wheels?

Grit size on grinding wheels runs from coarse, medium to fine. Coarse being 16 - 24 grit, medium 36 - 60 grit and fine being 80 - 120 grit. The superfine range runs from 150 and higher. Grinding wheels are usually between 24 and 100 grit. Jointing & honing stones used for grinding wheel maintenance are 150 grit or higher.

What is glasing in grinding wheels?

When the surface of the grinding wheel develops a shining and smooth texture, it is said to be glased. This appearance indicates that the grinding wheel is blunt which means the abrasive grains are not sharp to grind the workpiece with precision. Glasing is usually caused by grinding hard materials that are too hard for the grinding wheel abrasive material.

How to know if the grinding wheel needs dressing?

As the sharpness of the grinding wheel dulls from the glasing & loading, dulled chips and grains are removed with a suitable dressing tool to expose the sharp cutting edges while making recesses for the chips.

Change Country

Change Country