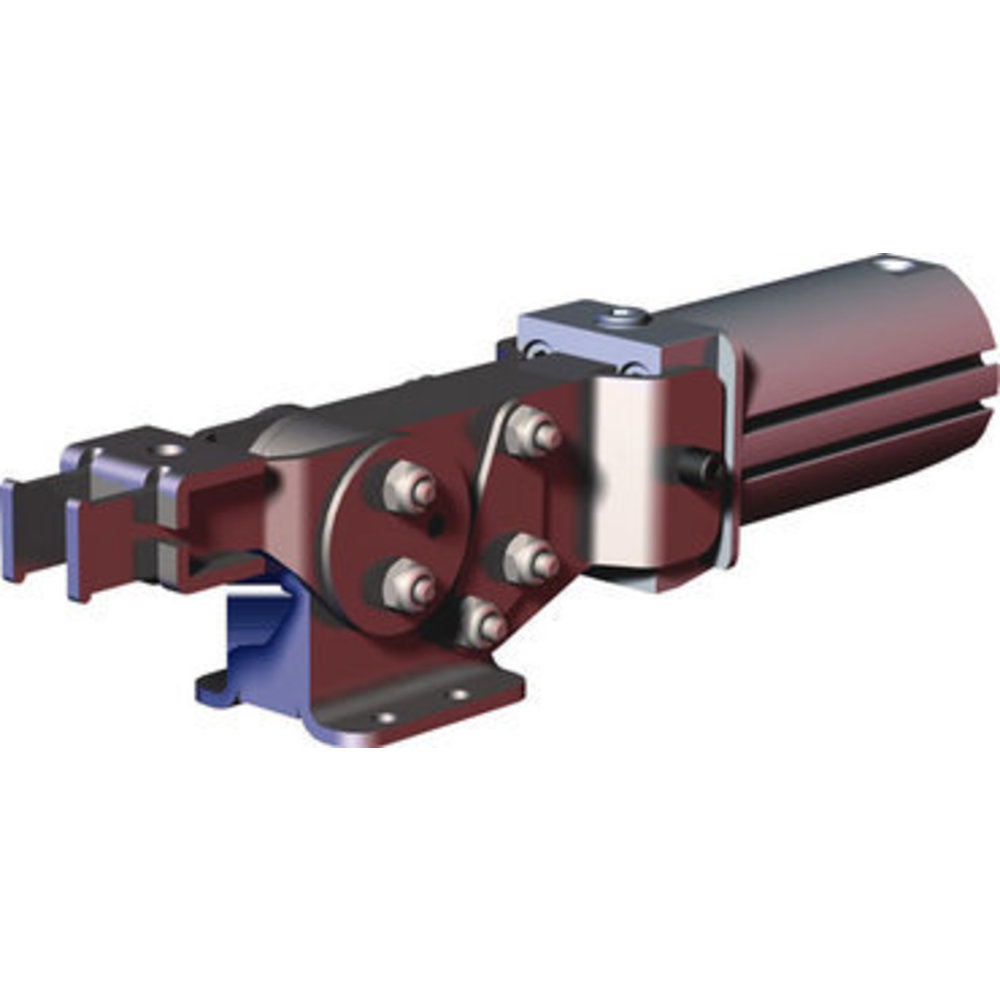

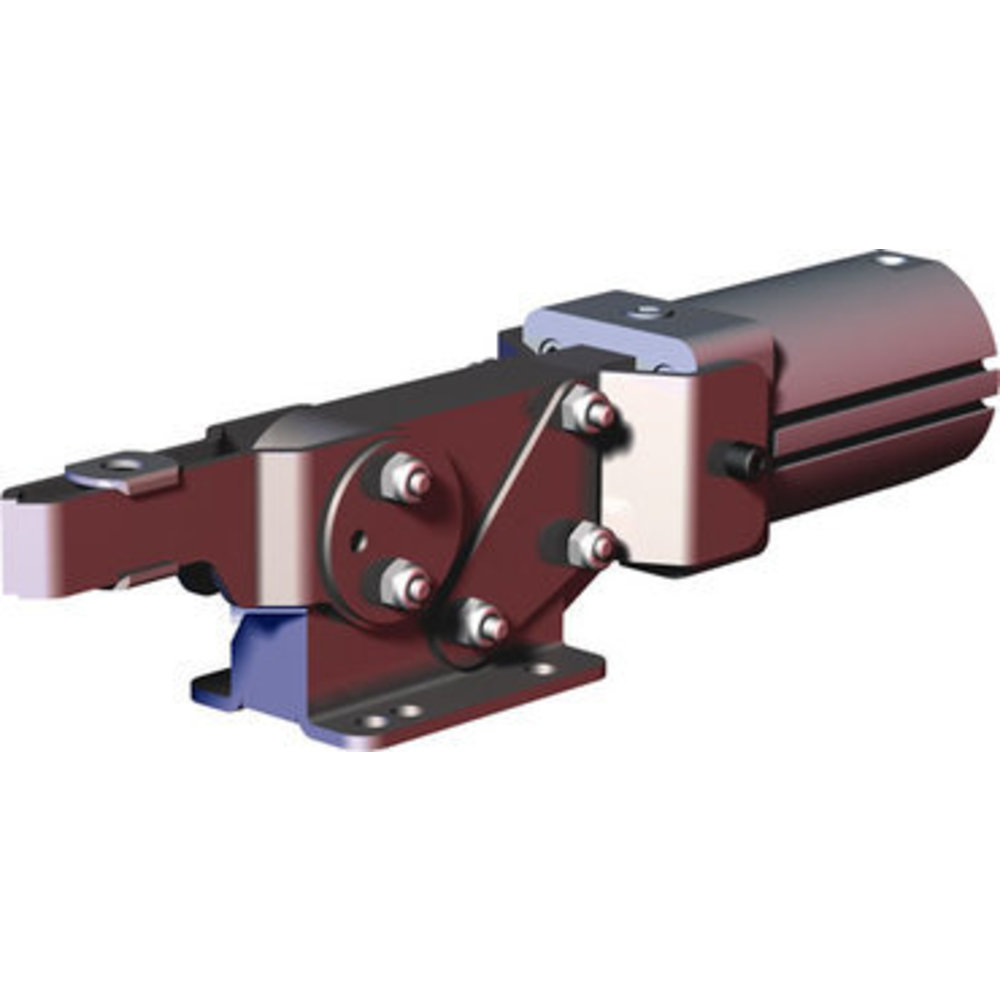

8021, 8071 Series Pneumatic Toggle Clamps

Destaco 8021 & 8071 Series pneumatic toggle clamps are ideal for quick clamping applications in the automotive and food & packaging industries. These pneumatic clamps are equipped with an air actuated cylinder with an input port for connecting to the compressed air source and then utilising the compressed air to apply clamping pressure for holding the workpiece in place. These pneumatic clamps have over centre toggle action linkage combined with a pneumatic cylinder to provide a device that is easily adaptable for a wide variety of applications. Destaco 8021 & 8071 Series pneumatic toggle clamps are completely self contained & require just a single pressure source. These clamp units are sensor ready for both round and T slot style sensors, and feature an in built flow restriction system. This eliminates the need for external flow controls, thus ensuring smooth clamping. They feature an enclosed design for MIG & spot welding in dirty environments. These pneumatic toggle clamps have a non pivoting cylinder that can easily be hard-piped into fixtures. These toggle clamps are actuated by double acting pneumatic cylinders delivering a maximum clamping pressure of 145 psig, and are integrated with hardened bushings & pins at all pivot points for long service life. These clamps are capable of withstanding loads up to 450 lb and come integrated with U bar clamping arms for keeping workpieces safely in place. Destaco 8021 & 8071 Series pneumatic toggle clamps feature a magnetic piston ring for accurate position sensing and an ergonomic handle grip for utmost operator comfort & reducing hand fatigue. Destaco 8021 & 8071 Series pneumatic toggle clamps can be operated at temperatures ranging between -14 & 194 degrees F.

Uses

Destaco 8021 & 8071 Series pneumatic toggle clamps are ideal for applications such as welding, grinding, assembling and light machining in the automotive and food & packaging industries.

Frequently Asked Questions

What are pneumatic toggle clamps?

Pneumatic toggle clamps feature the same basic design and operation as manual hold-down or straight-line toggle clamps, but are operated pneumatically. They are completely self-contained and require only a pressure source hook-up.

How do latch clamps work?

These pull action latch clamps depend on 3 main components - a handle for operating the tool, a clamping arm for contact point between the work item & clamp, and a base for attaching the clamp to the surface. Once the simple linkage system of the clamp is put in the over-centre position, the handle is pulled horizontally for creating force parallel to the base and squeeze-holding the work items.

Which grease is ideal for Destaco clamps for their rebuilding?

A coupling grease like Mobil XTC should be used when dealing with Destaco mechanical clamps, while the Magnalube G grease is great for use with pneumatic cylinder seals.

What does holding capacity mean in terms of clamps?

The holding capacity or the holding force depicts the clamp's capability to hold down equipment or sheet metal on assembly lines or during similar manufacturing processes.

What is the significance of the red colour of the handle of Destaco clamps?

There is no such significance of colour of the clamp's handle, as it only represents a recognisable area. This helps operators in finding the handle quickly & easily.

What does clamping force mean?

Clamping force is the amount of force actually applied to a workpiece by closing & locking the clamp. It is normally less than the stated holding capacity. The actual clamping force depends on various factors, including cylinder bore, cylinder area, spindle position (clamping arm length) and available air pressure. In most cases, the clamping force is approximately 2 to 3 times the force exerted by a pneumatic cylinder.

Does Destaco supply any water resistant clamp sensors?

Yes, Destaco also supplies inductive sensors designed in accordance with IP65 standards to ensure protection from powerful hydraulic jets, dust & heavy rain.

Change Country

Change Country