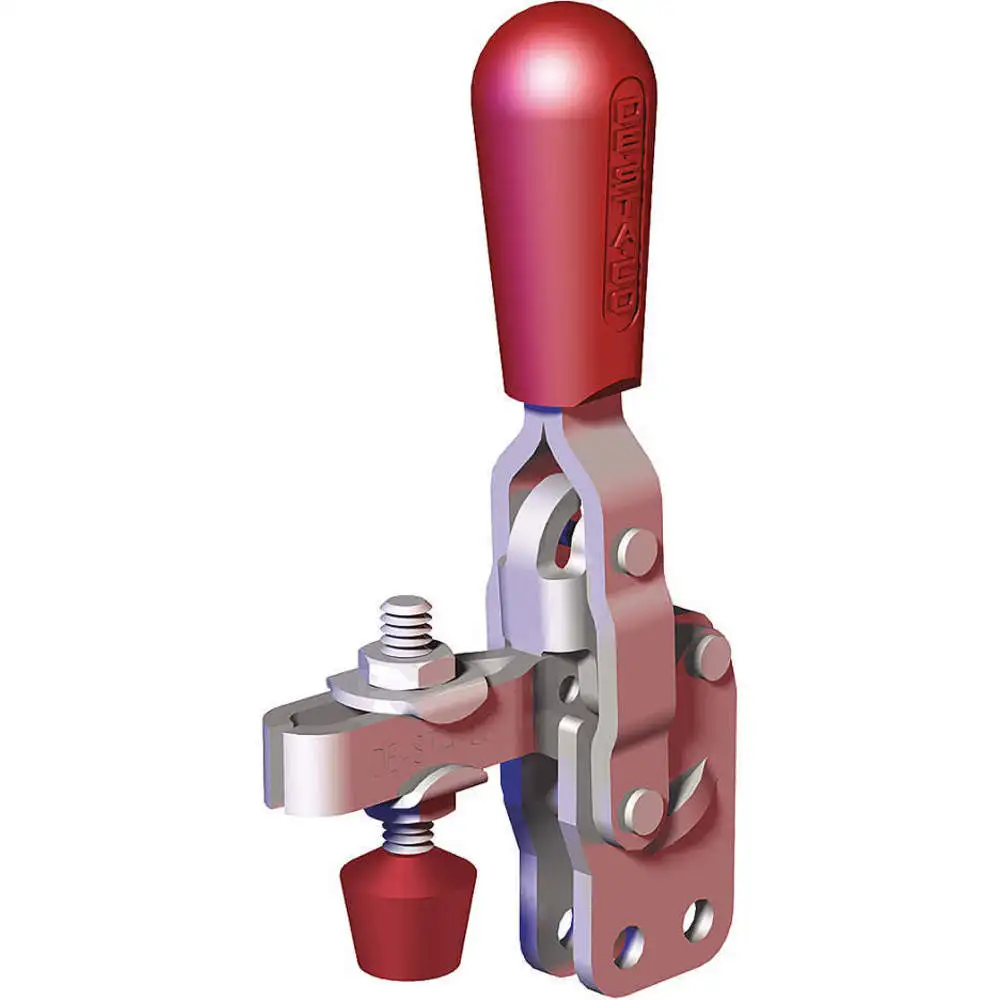

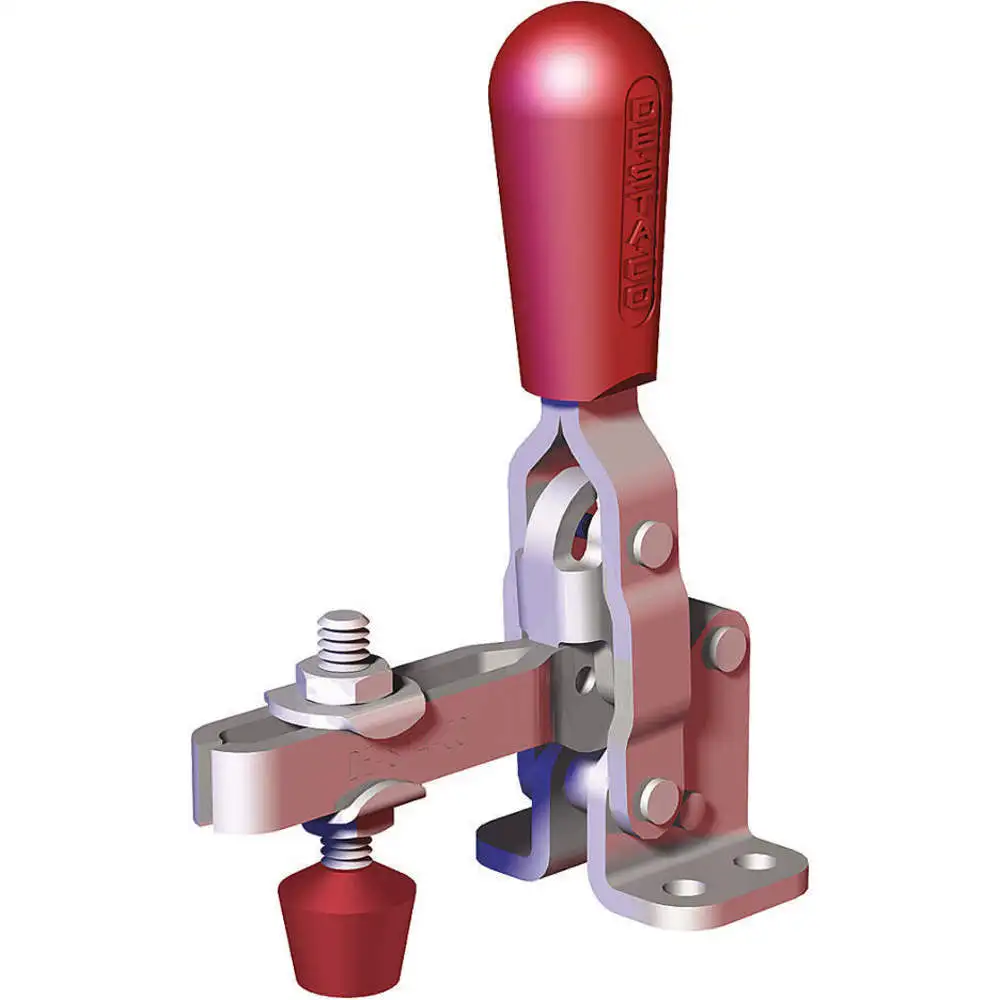

202 Series Vertical Hold Down Clamps

These Destaco 202 Series vertical hold down toggle clamps or heavy duty hold-down clamps are ideal for mounting to tight spaces in the . They come with lever handles that are pushed to the upright position, to hold workpieces firmly in place when the clamps are engaged. They have a fixed design for securing and loosening materials without moving the clamps. These clamps have a flanged or straight base with threaded holes for easy installation. They are suitable for checking fixtures, light machining, assembling & testing, welding, drilling, milling and woodworking applications in the automotive, aerospace, and food & packaging industries. They are used for applying downward clamping force by increasing the applied load through toggle mechanisms and are integrated with precisely machined components having hardened & ground pivot pins and bushings for prolonged service life. These weldable vertical toggle clamps deliver flexibility to position the handle as they incorporate an ergonomic, T handle or vertical handle options with fatigue less handle grip. These vertical hold-down clamps are made of stainless steel construction for resisting corrosion on exposed surfaces and are capable of withstanding loads up to 250 lb. These clamps offer a stationary alternative to removable C clamps or spring clamps while securing material to a work surface, and have a flanged or straight base with threaded holes for quick & secure surface or blade mounting, respectively. They further come equipped with a long handle with great hand clearance that can exhibit a minimum of 90 degrees opening angle for additional safety. These clamp's bolt patterns are interchangeable with the 2002 Series toggle clamps. Further, they accommodate M6 or 1/4 inch spindle assemblies to provide maximum clamping force. These Destaco 202 Series vertical toggle clamps are available in U bar or solid bar clamp arm variants on Raptor Supplies for adjustable spindle location and customised attachments or fixed clamping, respectively.

Uses

These 202 Series vertical toggle clamps offer a broad combination of features, making them adaptable to applications such as checking fixtures, light machining, assembling & testing, welding, molding, plastic injection and woodworking in the aerospace, automotive, food & packaging industries.

Frequently Asked Questions

Does Raptor Supplies also provide hold down clamps with Toggle Lock Plus feature?

Yes, Raptor Supplies offers Destaco hold down clamps with Toggle Lock Plus release lever to prevent accidental opening of clamps due to vibration.

How does a pneumatic toggle clamp work?

The toggle clamp actuates against the workpiece and stretches or compresses the equipped linkages for keeping the workpiece in a stationary position.

Does Raptor Supplies offer replacement spindles for hold down clamps?

Yes, Raptor Supplies provides Destaco spindles for hold down clamps to replace worn out units, ensuring hassle-free operation and protection from damage caused by abrasion / twisting / flexing.

How do you adjust a toggle clamp?

After clamping, the force can be adjusted by loosening / tightening the spindle nut (supplied with the unit for protection from damage caused by abrasion, twisting or flexing).

How to install Destaco 202 Series vertical manual hold down toggle clamps?

These clamps feature a straight or flanged base having threaded holes and are used with spindle assemblies and flanged washers for ease-of-installation by simply securing materials to a work surface.

What is the difference between flange base and straight base mounting styles?

The flanged base allows secure surface mounting while the straight base enables blade mounting. Both mounting styles allow the units to be easily installed to surfaces and ensure easy attachment of the extensions.

Are vertical handle toggle clamps available in different materials?

Yes, apart from stainless steel, these vertical handle toggle clamps are also available in forged alloy steel construction with black oxide finish and carbon steel variants, with holding capacities up to 5000 lb.

Change Country

Change Country