Uses

Compressed air powers many devices. It can be used to push a piston (in a jackhammer), it can go through a small air turbine to turn a shaft (in a dental drill) or it can be expanded through a nozzle to produce a high speed jet (in a paint sprayer). Compressed air provides torque and rotational power for pneumatic tools, such as drills, brushes, nut runners, riveting guns and screwdrivers.

Features

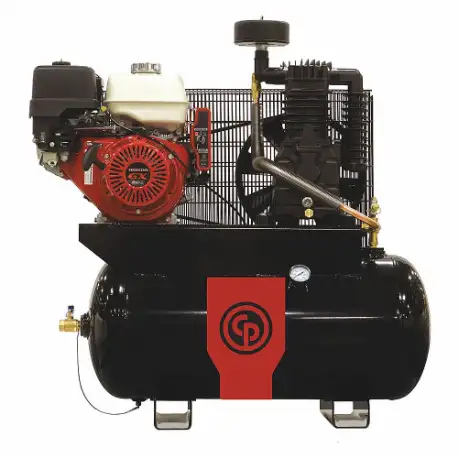

Chicago Pneumatic Splash Lubricated, Vertical Electric Air Compressors:

- These 2 stage compressors come with an aluminium head and coolers having deep fins that allow unmatched heat dissipation.

- They are equipped with balanced pistons and crankshaft for smooth and quiet operation.

Speedaire Pressure Lubricated Compressors:

- Speedaire air compressors are used in pneumatic climate control systems where low oil carryover is required.

- Pressure lubricated stationary electric air compressors use a pump for precise delivery of oil to internal components. This ensures that components are more evenly and thoroughly lubricated than the splash method, extending the life of the air compressor.

- These high performing air compressors require regular oil refill and change.

Speedaire Duplex Electric Air Compressors:

- Duplex stationary electric air compressors have two pumps and two motors.

- These units are designed to evenly distribute workload between the two pumps & motors, allowing each of them more cooldown time between cycles. This increases the compressor's operating life and ensures continuous operation if one pump or motor fails.

- These air compressors are used for applications that need reliable and continuous operation.

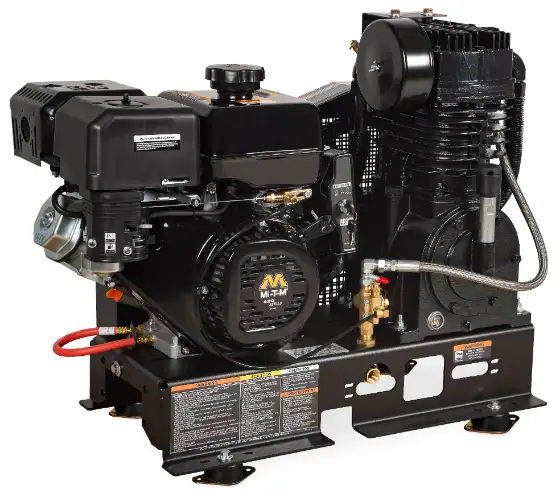

Ingersoll-Rand Tank Mounted, Splash Lubricated, Horizontal Electric Air Compressors:

- These compressors are designed to provide compressed air where electric power is not readily available.

- They are ideal for use in fleet & field service applications, remote pneumatic applications and emergency production lines.

- These models are incorporated with fuel efficient idle control and advanced safety features including low oil level shutdown for gas engines

Working Mechanism

Air compressors work by forcing atmospheric air under pressure to create potential energy that can be stored in a tank for later use. Just like an open balloon, pressure builds up when the compressed air is deliberately released, converting the potential energy into usable kinetic energy. This energy transfer can be harnessed to power various pneumatic tools.

Industrial air compressors work similarly to combustion engines. Generally, the process of air compression requires a pump cylinder, piston and crankshaft to transfer energy for a wide variety of tasks. These basic components can supply air for filling up objects like tires or inflatable pool toys, or they can supply power for operating tools such as drills, nail guns, grinders, sanders and spray guns.

Standards and Approvals

Stationary electric air compressors are constructed in accordance with ISO standards to ensure improved environmental health, user safety and enhanced performance.

Frequently Asked Questions

How to maintain air compressors?

- Drain the tank: When your work is finished, you'll need to open the drain valve on the underside of the tank to release moisture. This needs to happen after every use, as water can corrode metal. Turn off the compressor first. When you open the drain valve, the escaping air will also push any moisture collecting around the bottom of the tank, out. Alternatively, turn the pressure regulator knob to switch off the hose's air supply and turn off the compressor. Then, wait for the pressure to leave the compressor. You can pull the pressure relief valve to release air faster, but this won't release the moisture.

- Keep an eye on the air filter: Get into the habit of checking the air filter every time you use it. Too much gunk begins to starve the motor and might cause it to fail. Replace it when you start to see a significant amount of build-up on it.

- Check oil: After you've finished storing away hoses, check the oil level again, and refill it if it has dropped too low. Once a year, you'll want to replace the oil altogether.

How long can an electric compressor run?

Depending on the size and type of compressor, air compressors can operate from a few hours up to 24 hours a day, seven days a week.

Change Country

Change Country