Uses

Drum lifters are widely used for handling steel, plastic and fibre drums in food & packaging, recycling, material handling, marine, chemical and pharmaceutical industries.

Features

- Morse Drum overhead crane lifters are meant for transporting the drum in an upright position.

- They feature a built-in plate that supports the drum and load binders for securing the drum in position.

- These drum lifters come integrated with fork pockets and fork mount hooks to be attached with a monorail, crane or chain block for moving the drums.

- Their heavy-duty steel / stainless-steel construction protects the drum lifter against weathering damages.

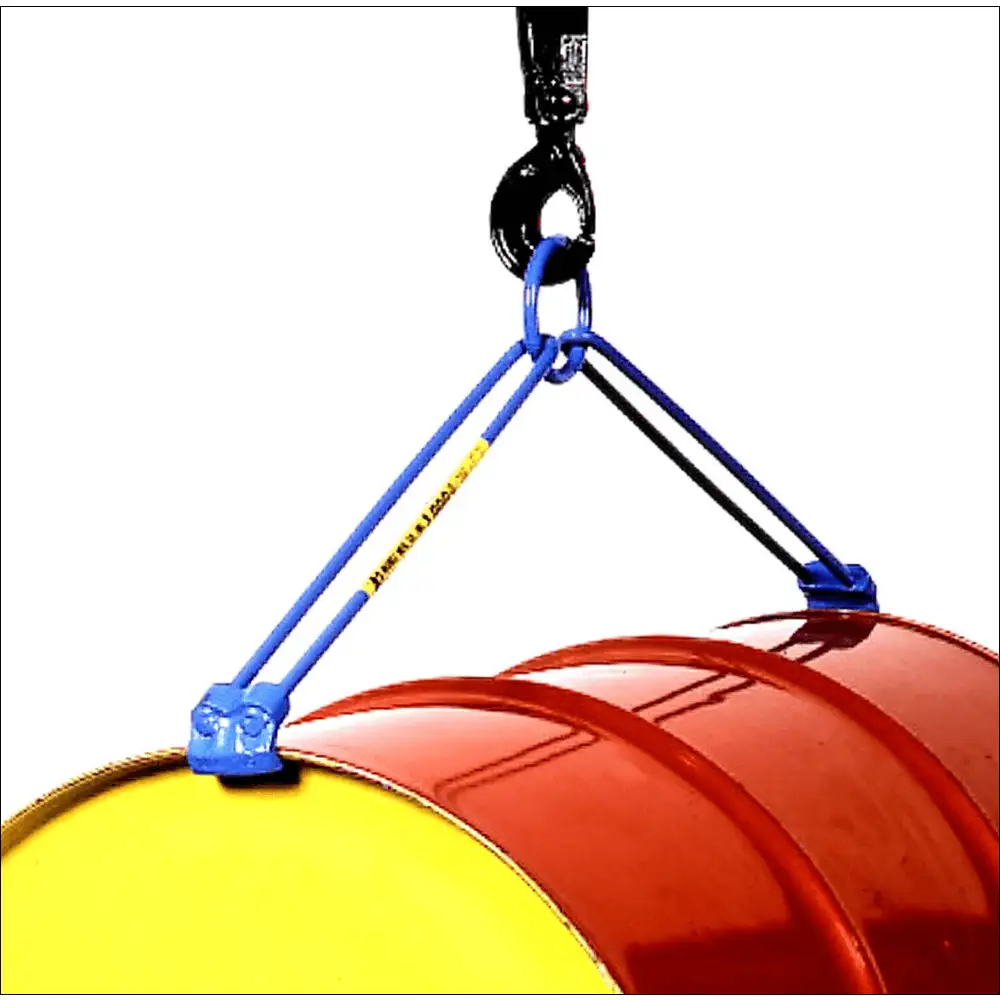

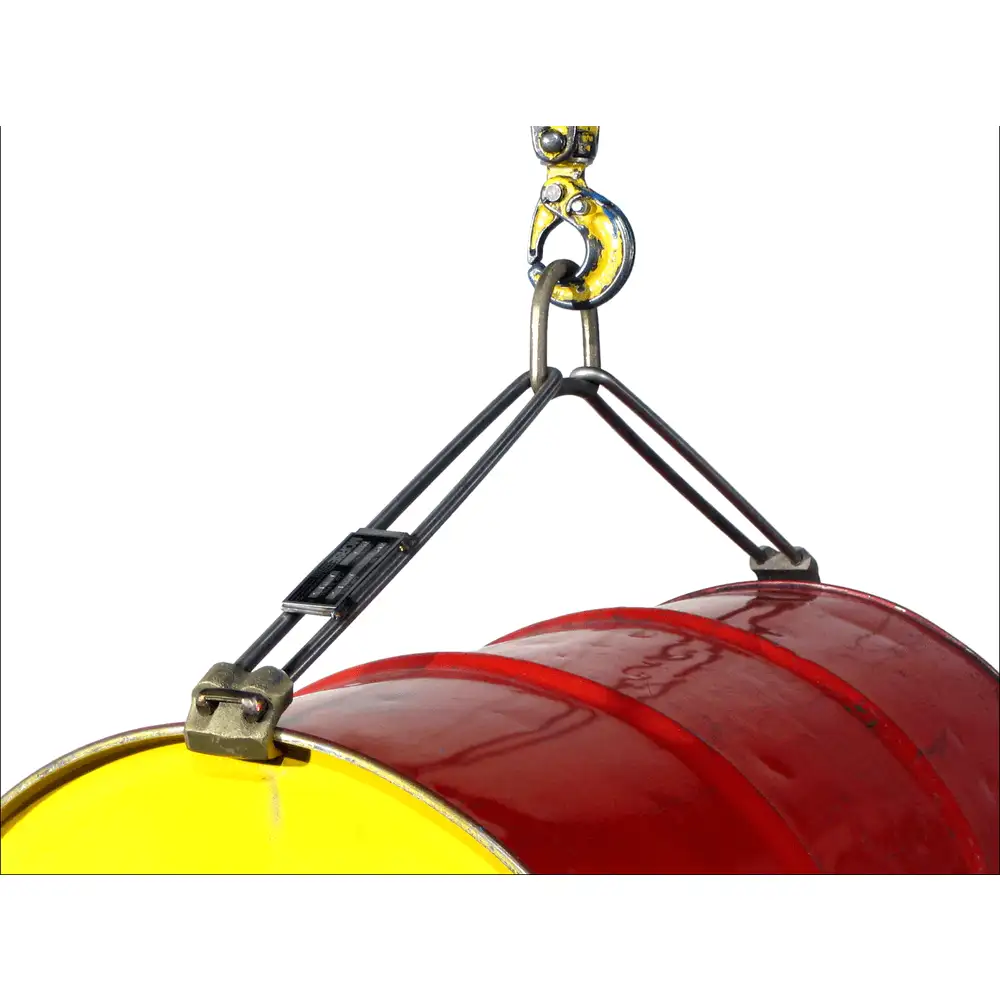

Justrite overhead drum lifters feature tong-style design for lifting heavy drums by simply gripping the drum chime. These rugged lifters resist accidental opening / bending under heavy loads.

- Portable drum lifters are suitable for applications that require the user to lift and rotate the drum to safely dispense into containers.

- They feature compact base for a small footprint and manoeuvrability in confined spaces with a tight turning radius.

- These drum lifters can easily accommodate steel, plastic & fibre drums and rotate them up to 360 degrees.

- Some models also include a built-in scale indicator for weighing the drum weight with accuracy while dispensing the material.

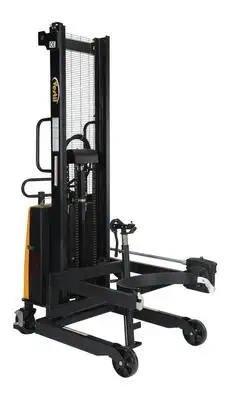

Drum stackers from Dayton & Vestil are designed for lifting & stacking heavy drums in commercial warehouses. The hydraulic lifting mechanism of these lifters prevents them from losing balance (even mid-transit) and facilitate fatigue-free drum stacking in heavy workload environments.

Valley Craft drum loaders feature three-wheel design with a rear-mount swivel caster for maximum manoeuvrability in tight spaces. These drum loaders are further integrated with a brake for preventing unwanted movement.

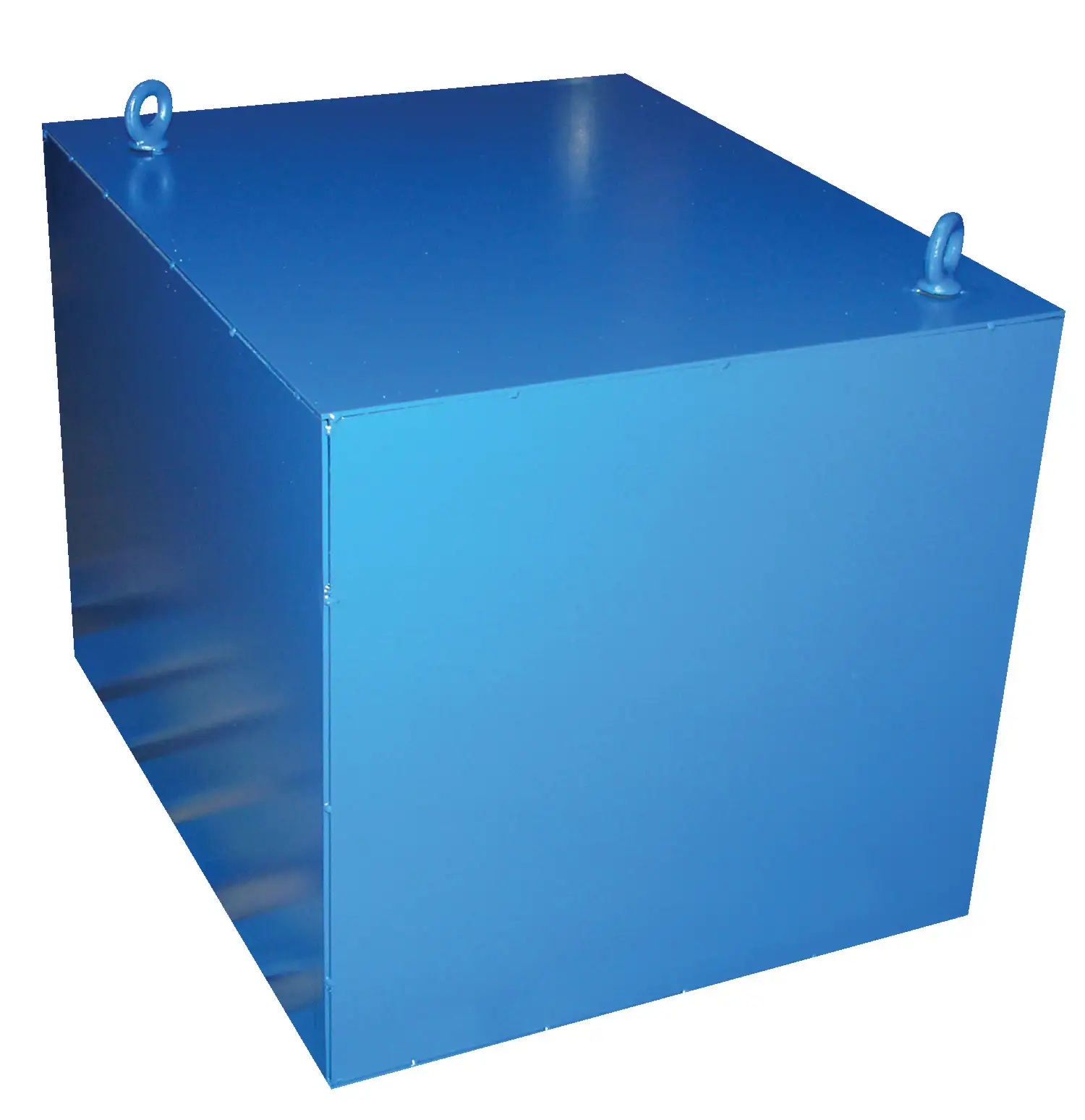

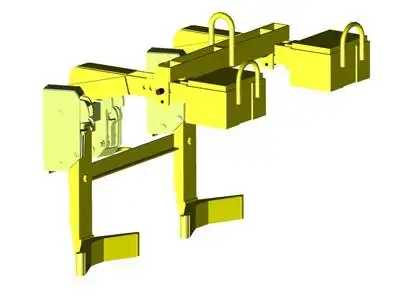

Morse Drum Overhead Crane Lifters

- They feature a built-in plate that supports the drum and load binders for securing the drum in position.

- These drum lifters come integrated with fork pockets and fork mount hooks to be attached to a monorail, crane or chain block for moving the drums.

- Their heavy-duty steel / stainless-steel construction protects them against weathering damages.

Justrite Overhead Drum Lifters

- They feature a tong-style design for lifting heavy drums.

- These portable drum lifters are suitable for applications that require the user to lift and rotate the drum to safely dispense into containers.

- They feature a compact base for a small footprint and manoeuvrability in confined spaces with a tight turning radius.

- These drum lifters can easily accommodate steel, plastic & fibre drums and rotate them up to 360 degrees.

Working Mechanism

The overhead drum lifters are easy & safe to operate in contrast to traditional lifting equipment. These lifters are used in conjunction with overhead cranes and a chain to hold & lift the drum using the rim. The directional flexibility of the drum depends upon the crane movement and can be easily repositioned / relocated / detached by unlocking the drum lifter's locking mechanism.If the requirement is to lift & transport drums with or without the upper rim, portable drum lifters are an ideal choice. These hydraulic drum lifters feature swivel casters for reducing the frictional losses on factory floors. They can also tilt / rotate the drum, allowing the inner content to flow easily.

Standards and Approvals

The drum lifters provided by Dayton, Eagle, Enpac, Grainger, Justrite, Morse Drum, Vestil, Valley Craft and Wesco meet OSHA industry standards for user safety.

Frequently Asked Questions

Can drum lifters be used for both horizontal and vertical orientation?

Some drum lifters can be used in both horizontal and vertical orientations. These lifters are also called 'bi-directional' drum lifters having a pivot or hinge mechanism that allows them to easily convert the orientation from horizontal to vertical and vice versa, allowing great versatility in different lifting and transporting applications.

Are there manual or electric drum lifters?

Yes, oth manual and electric drum lifters are available for different industrial applications. Manual drum lifters are operated by using a hand crank or lever to lift and transport drums. On the other hand, electric drum lifters are powered by an electric motor and operated by a control panel or remote control. They lift and transport drums with minimal physical effort, making them more ergonomic for continuous use.

Do I need any special training to use a drum lifter?

It is recommended that operators receive proper training before using a drum lifter. Proper training should cover the following topics:- Safety: Operators should be made aware of the potential hazards associated with drum lifters, such as falls or chemical spills.

- Operating procedures: Users should be familiar with the proper procedures for operating drum lifters. This includes basics like how to attach and detach the lifter from the drum, how to properly transport the drum and how to safely secure the drum in place.

- Weight limits: Operators must be familiar with the weight limits of the drum lifter to prevent any mishappening.

- Use of PPT kits: Users should know appropriate personal protective equipment when operating the lifter, including hats, safety glasses and steel-toed boots.

- Inspection & Maintenance: Users must be familiar with inspection & maintenance procedures. This includes checking for wear & tear, lubrication / relubrication of moving parts and troubleshooting problems.

Which safety features are important in a drum lifter rotator?

Safety features include locking mechanisms to secure drums during rotation, load capacity indicators and emergency stop buttons to ensure safe drum handling.

How do you operate a hydraulic drum lifter?

To operate a hydraulic drum lifter, pump the hydraulic handle to raise the drum and a release valve is used to lower it safely.

What are the advantages of using steel drum lifters over other materials?

Steel drum lifters offer durability, resistance to corrosion and the ability to handle heavy steel drums, making them ideal for rugged industrial environments.

Change Country

Change Country