Features

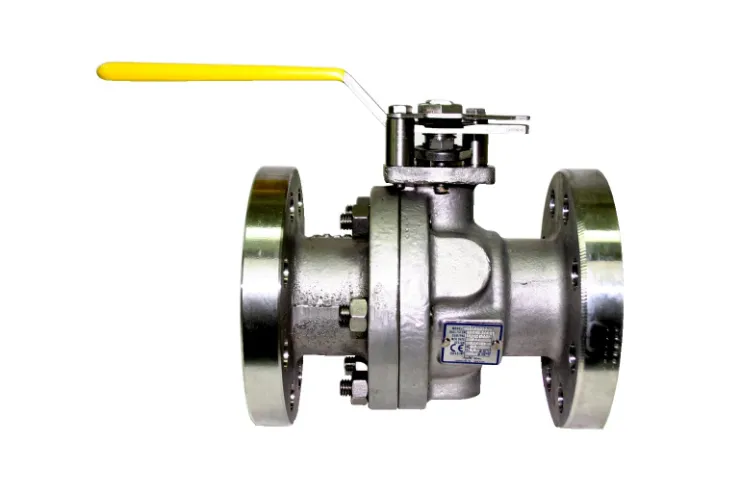

- Apollo 83B-140 Series ball valves feature a swing-out centre section for easy maintenance and repair without disrupting the pipeline. These ball valves have a pressure-balanced solid ball for bleed and drain port functionality. They come with compression-controlled spiral-wound gaskets for a secure seal even under high-pressure conditions. These ball valves are equipped with a statically grounded ball, stem and body for safety against static electricity.

- The brand's 82-140 Series ball valves feature a dezincification resistant bronze construction for durability and resisting corrosion on exposed surfaces. These ball valves have an adjustable packing gland for reducing maintenance needs. They come with a blowout-proof stem for preventing stem ejection during operation. These ball valves have RPTFE seats to prevent leakage. They are equipped with a full port ball for unrestricted flow and minimising pressure drop across the valve.

Speedaire Brass Filter Ball Valves

- They are equipped with an in-built strainer for taking out pollutants when the air passes through them.

- These brass filter valves feature brass construction for enhanced durability and corrosion resistance.

- They are available in 1/4, 1/8, 3/8 and 1/2 inch pipe sizes.

Spears 5024 Series Ball Valves

- They have PVC / CPVC construction for durability and corrosion resistance.

- These valves offer vertical 3-way / horizontal diverter design for ease of operations.

- They come in L-port, multi L-port & T-port ball configurations as per the compatibility with the equipment.

- They are interchangeable with all True Union 2000 valves and mate with Union 2000 pipe unions.

- They further feature a polypropylene handle and a built-in handle lockout for increased safety.

Watts Ball Valves

- They feature brass / bronze / cast bronze / forged brass / lead free copper silicon alloy construction for structural rigidity and enhanced performance.

- These valves have brass / chrome plated brass / stainless steel / 304 stainless steel / 316 stainless steel balls for enhanced durability and corrosion resistance.

- They come with lever / locking lever / tee type handles for tight grip and improved hold.

- These ball valves can withstand temperatures ranging from 73 to 450 degrees F.

Apollo 70-190 Series Ball Valves

- These ball valves have bronze construction for high tensile strength and aesthatic appearance.

- They are available in automatic drain, grounded, side vented ball, stainless steel latch-lock lever & nut, standard and stainless steel lever & nut variants.

Frequently Asked Questions

How to install a ball valve?

Insert the Apollo ball valve's input and output into your threaded assembly and screw them. Before installing the handle, make sure it is properly installed (parallel is open).

Are ball valves suitable for throttling applications?

While Apollo ball valves can be used for throttling, they are not as precise as other types of valves. So, if you want a valve only for throttling purposes, then you should go for Apollo globe valves.

Are the quarter-turn valve and ball valve the same thing?

A quarter-turn valve is not the same as a ball valve, but a ball valve is a type of quarter-turn valve. A quarter-turn valve is a general term for any valve that requires only a quarter-turn (90 degrees) of the valve handle or lever to move from fully closed to fully open or vice versa. So, while a ball valve is a type of quarter-turn valve, not all quarter-turn valves are ball valves.

What is the difference between a two-way and a three-way ball valve?

A two-way ball valve has only two ports and can only allow or disallow the flow. A three-way ball valve, on the other hand, has three ports and can be used to divert, mix or isolate flows from multiple directions.

How do I choose suitable ball valves for my application?

- Consider the appropriate valve size based on flow rate and your application requirements.

- Ensure the valve can withstand the maximum pressure required for the application.

- Select the proper end connections for compatibility with the piping system.

How do ball valves compare to other types of valves?

They provide better sealing, require less force to operate, have lower pressure drops and offer faster response times.

How can I maintain these ball valves?

Proper maintenance of ball valves involves periodic inspection, lubrication of seals & bearings and addressing any signs of leakage or damage.

Change Country

Change Country