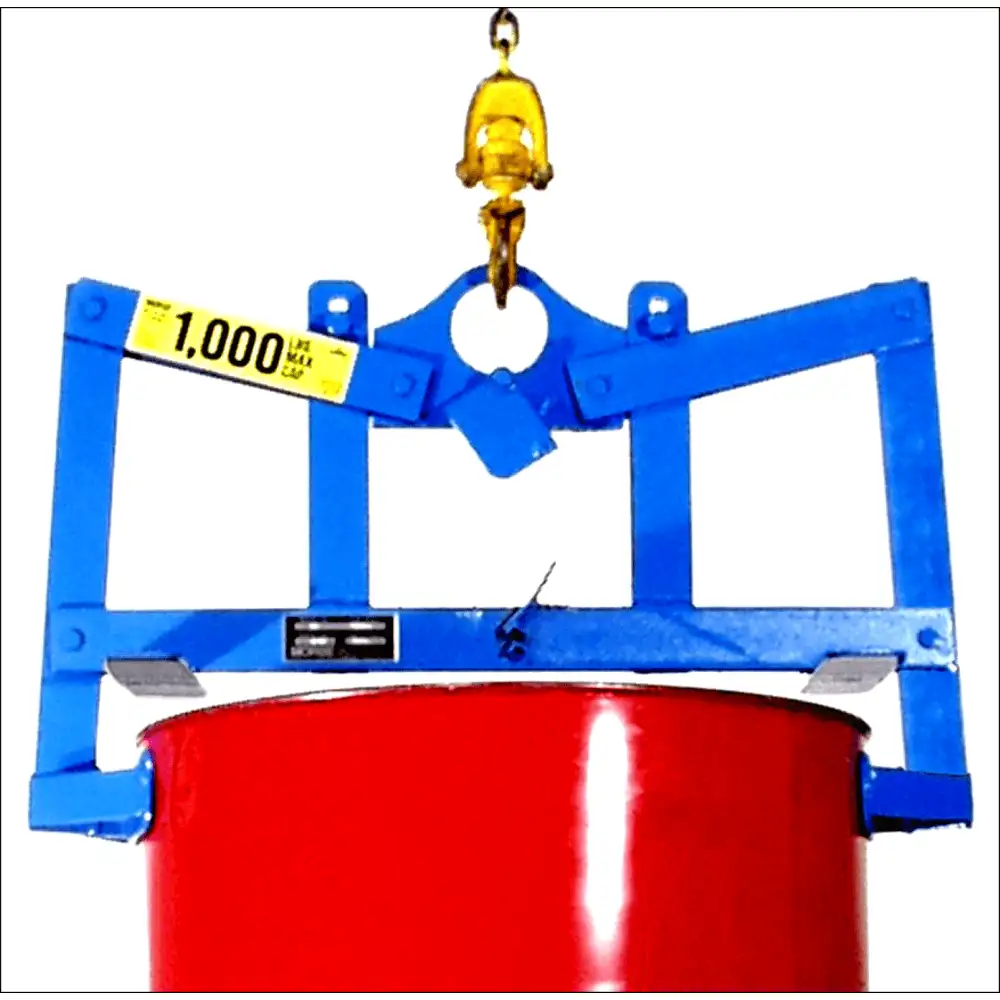

Drum Lifters(29 Products)

Drum Rollers(82 Products)

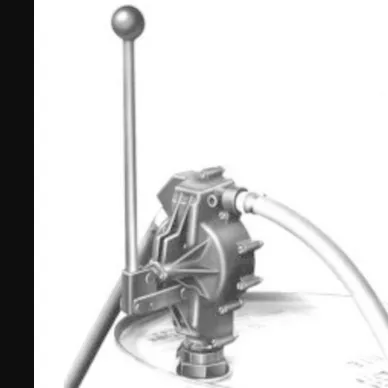

Drum Barrel Pump AccessoriesHand-operated, self-priming hand pumps designed to dispense liquids at a controlled discharge rate of 0.95 litres. Feature a double-action piston to dispense liquid on both forward and back strokes. Available in cork-nitrile, EPDM and Viton gasket variants

(5 Products)

Pail / Can HandlersSuitable for lifting and pouring a 5-gallon metal can or plastic pail weighing up to 68 kg. Feature hand cranks for raising the pail and hand wheels for controlling the pour angle. Provide drum pail speeds up to 23 rpm(37 Products)

Drum Hand TrucksMorse 2 / 3 / 4 wheel drum hand trucks load & unload heavy drums with ease and move them in narrow aisles & spaces. They feature steel construction for rigidity. These hand trucks have a maximum load capacity of 1200 lb and are also available in stainless steel variants.(9 Products)

Drum TumblersDesigned for using a corner-over-corner agitation mechanism, ideal for thoroughly mixing the contents of closed drums. 310 Series Tilt-to-Load drum tumblers featuring power lifts for loading the drum onto the drum mixer at ground level. Comes equipped with a drum holder(29 Products)

Drum Cradles and TippersMorse Drum includes drum cradles, upenders and tipping levers having a maximum capacity of 700 lb. They move & tilt the drums & dispense contents inside them. These drum cradles feature roll-over mechanism for less strenuous drum lifting and have an all-welded frame.(3 Products)

Drum Heaters(15 Products)

Drum Safety EnclosuresOSHA compliant safety enclosures, control packages, tumblers & rollers for safe drum handling in risk prone areas. Enclosures provide a barrier between workers and drum handling equipment. Available in fenced and completely closed models with an automatic power shut-off feature(136 Products)

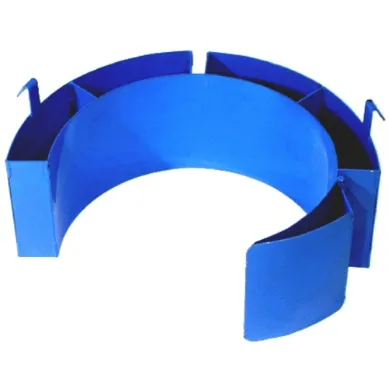

Drum Cones And CollarsMorse Drum 45-degree / 65-degree / asymmetric drum cones control the dispensing of drum contents using an easy-to-operate valve. They are made of steel or aluminium and are available in variants to handle drum diameters ranging from 15-7/8 to 23-3/8 inches.(103 Products)

Drum PourersUsed for raising and pouring contents from a heavy drum by controlling the drum height and pouring angle, simultaneously, while dispensing. Made of carbon / stainless-steel for shock resistance. Allow turning the drum up to 360 degrees in either clockwise or anti-clockwise direction(239 Products)

Drum AdaptersMorse Drum adapters include bracket assembly kits, drum adapters, hand wheels, hand cranks, rim clamp kits & straps. They are suitable for easy manoeuvring of drums having small diameters, in factories & laboratories and are available in diameters ranging from 14 to 22 inches.(33 Products)

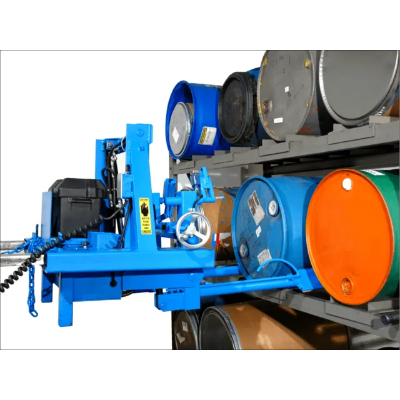

Drum RackersDesigned for moving, lifting and placing drums horizontally on a rack. Feature a locking mechanism to prevent unnecessary drum movement. Capable of withstanding loads up to 800 lb. Available in heights of 56, 72 and 102 inches(38 Products)

Drum Dollies(15 Products)

Drum PalletisersMorse Drum palletisers are used for powerlifting drums safely in warehouses and manufacturing plants. They have a V-shaped base to service pallet corners and are available in electric motor, air, battery and manually operated variants.(29 Products)

Blocks and SheavesMorse Drum blocks and sheaves lift heavy loads via heavy-duty wire aircraft cables or ropes. They allow wires or ropes to move freely with minimal wear & friction on the cable. These sheaves are ideal for redirecting a rope / cable and power transmission.(2 Products)

Drum Lifter AccessoriesMorse Drum lifter accessories are installed on 185A-HD & 285A-HD Series forklift karriers for lifting, stacking dispensing or turning drums while moving. They feature stainless-steel construction to resist oxidation on exposed surfaces and eliminate the need for a pull chain tilt-control facility.(32 Products)

Valve AccessoriesIncludes electrical or mechanical actuation mechanisms, fluid control mechanisms & integral casings, and related connectors, fasteners & external sensors(4 Products)