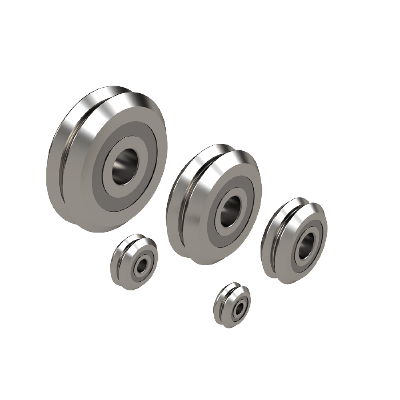

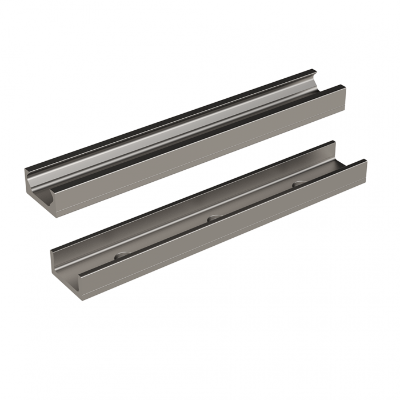

Bishop Wisecarver manufactures high-quality linear motion products and linear actuators for the aerospace, automotive, food / beverage and general automotive industries. The brand's products are suitable for carton filling equipment, pick and place racks, washdown systems and conveyor belts. Bishop Wisecarver carriage assembly combines linear and rotary motion to follow virtually any path. It features rings, curved segments, straight slides and carriages for travelling in both linear and rotary motion. These carriages are made from anodised aluminium while the ring slides have high-quality steel and zone-hardened construction on the V edges. The brand's slide rings are ideal for rotary and track system applications. Selected models with precision ground finish & hardened vee faces are used for smooth gliding and are ideal for applications that require curved or circular track motion. Different models of manual and actuated linear guide systems are available in corrosion-resistant carbon, steel and polymer construction variants.

See More